-

Hi everyone,

As you all know, Coffee (Dean) passed away a couple of years ago. I am Dean's ex-wife's husband and happen to have spent my career in tech. Over the years, I occasionally helped Dean with various tech issues.

When he passed, I worked with his kids to gather the necessary credentials to keep this site running. Since then (and for however long they worked with Coffee), Woodschick and Dirtdame have been maintaining the site and covering the costs. Without their hard work and financial support, CafeHusky would have been lost.

Over the past couple of weeks, I’ve been working to migrate the site to a free cloud compute instance so that Woodschick and Dirtdame no longer have to fund it. At the same time, I’ve updated the site to a current version of XenForo (the discussion software it runs on). The previous version was outdated and no longer supported.

Unfortunately, the new software version doesn’t support importing the old site’s styles, so for now, you’ll see the XenForo default style. This may change over time.

Coffee didn’t document the work he did on the site, so I’ve been digging through the old setup to understand how everything was running. There may still be things I’ve missed. One known issue is that email functionality is not yet working on the new site, but I hope to resolve this over time.

Thanks for your patience and support!

You should upgrade or use an alternative browser.

TR650 fender/license plate holder eliminator ideas

- Thread starter ebrake

- Start date

Gedge

Husqvarna

A Class

View attachment 23977

Here is the exploded parts description from the kit's directions. #1 is the mail tail piece assemble - Made of steel. #2 is the new license plate light (LED). 3,4, & 10 are the turn signal brackets. 5-9 are the spacers and bolts to put the tail lock piece into #1. 11 is shrink wrap for the license plate light wires. 12 is a stick on round reflector??? The largest issue I ran into was the fact that the turn signal bracket were not threaded to accept the screws (#3) and I had to thread them. Other holes used clips that the bolts would screw into but the holes needed to be bored out to accept the standard screws removed initially.

Cheers,

Leo

Glad it wasnt just mine like that.. I did visit R&G and told them about the holes being too small and the indicator holes not being tapped...they are going to modify future kits so they should be a bit easier to get on.......

Leo Fisher

Cafe Husky - Contributing Member

The 2 pound chunk of steel is the issue, the way I see it. It's freaking heavy. The plastic should be able to take a fair amount of jostling and still be fine...as long as that weight isn't adding too much momentum to it.

That said, I was going to go with the tail tidy, but the wait wasn't something I was interested in. Anyway, a 7" (roughly I don't recall the exact measurement) length of 1x1/8 flat aluminum stock, some m5 and m6 machine screws, a 10 pack of m5 washers, and nylocks for both. This cleaned up the back end, should make it more durable and still keep me mostly clean (still had spray up the back of my jacket from riding in the rain Saturday, but it really wasn't bad.

I ran a similar setup on my KTM 450 SMR and never had an issue. I do have the screws on it drilled and safety wired rather than relying on nylock nuts.

Total cost was about $10, and I still have 3 feet of aluminum left over, so figure realistic price under $5, or $2 had I remembered I already have a few feet of this stuff laying around.

My pictures are pretty rough, and no I didn't wash my bike after the gravel road, rain, etc ride from this weekend. But at least you can see what I did. The aluminum bar has the m5 screws through it, with 4 washers to space it from the fender (you'll see why with the side shot of the plate below). Then bolt those through the reflecter holes. No change made to the fender. Traced the shape of the license plate out and went to town with a hack saw and a file (I haven't been able to find my dremal since I moved a year ago

)

)My original plan was to make two bars, one for the bottom as well, but two hold it sufficiently and allow it to flex a bit more.

Leo Fisher

Cafe Husky - Contributing Member

kjackbrown

Keep on keepin on.

+1Cool, look forward to seeing it.

The m6 hardware I mentioned above isn't pictured, but that's what is securing the license plate rather than the cheap plastic screws that were easier to take off for the pictures.

Kawagumby

Husqvarna

AA Class

Does the tidy provide a steel connection from the frame to the back fender where the license plate/turn signals mount?

Thanks,

Tom

First how much weight can we take off the back end.

1- Steel bracket with reflectors 311gr.

2- Signal lights with bolts 131gr.

1- Reflector 21gr.

1- Chunk of plastic fender 50gr.

Total we can get rid of. 513grams

Now add 56 grams for these left over small signal lights I had from Eletrasport.

(Never did mount them on my TE510)

That’s around 457grams we can remove from the tail assembly…

Well that's pretty close to 1 LB in my books.

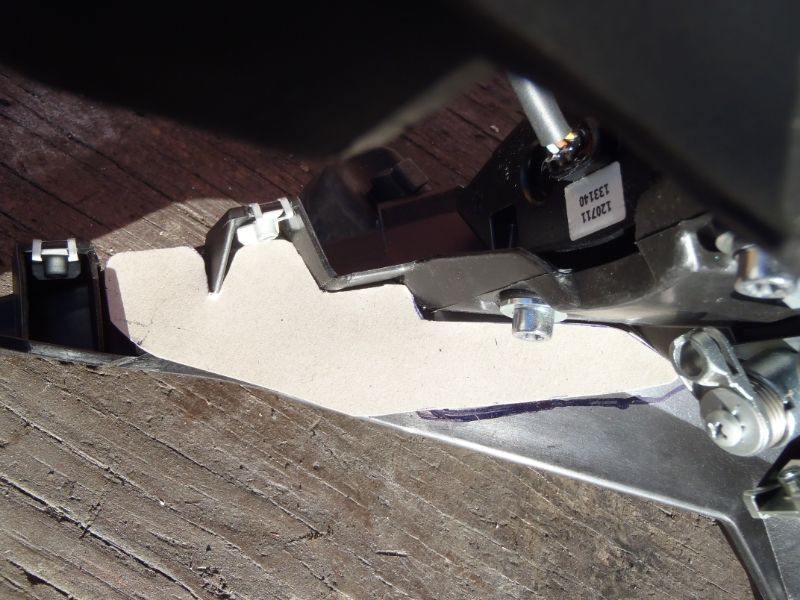

Here is what I did with the fender itself.

First I removed it and marked where the cracks on the fender were posted by Big T and krussel. Thx

Made some cardboard templates for the pieces I wanted to add to the fender to strengthen it.

The shape on the bottom is so it does not interfere with the rest of the internal parts of the fender once mounted on the bike again.

I used 3/16” aluminum and a couple of bends here and there to make them fit good.

And of course I used my favorite adhesive (Goop) to clamp in place.

Once mounted back in place it does move the License plate up a bit but still keeping most of the rear fender for muddy trails.

blakebird

Husqvarna

AA Class

I agree that the heavy metal piece swinging like a hyperactive pendulum is creating the cracking - and that a relatively simple fix will take care of it.

Get shot of the weight, move the plate mass up closer to the attachment points, and the stress induced on the plastic piece will be eased by a sufficient amount to keep the plastic/resin piece intact.

I checked the plastic/resin fender for stiffness - and it looks like it has stiffening pieces and bends in the right places, that it should be fine if it isn't subjected to a long lever arm shaking it constantly.

I came back from a long ride in the southern New Mexico desert on my 2012 TE 310 and that 'low hanging fruit' had all but shaken itself to death.

I shortened it up, used the EE plate and it was good to go.

IPA Brewer

Husqvarna

AA Class

My initial thought was that the pounding from the bumps fatigued it causing failure. But one of my more astute riding buddies suggested that the plate hit the rear tire during compression causing it to snap off. This is the likely failure mode, as it appears this is possible from eye balling what's left, and that the fender assembly was pulled away from where it snaps into the body work.

I will explore getting a new one under warranty, but am more concerned about how long it might take to get a replacement.

Anyone else had this happen? Any other theories? Kinda disappointing...

Thanks

Rich in PLacitas

blakebird

Husqvarna

AA Class

Watching my TR idle with the metal bracket wagging around like a pendulum looking to do some vibration damage... I put an Enduro Engineering plastic plate holder back there.

Hardly any weight now, it doesn't look like the plastic structure back there will die of vibration poisoning - but only time will tell.

farp

Husqvarna

C Class

The fender completely broke off, the left turn signal and tail light lens was smashed, and the seat lock cable latch was broken. I used baling wire to hold it all together until I got home. When the new parts arrive I'll try to reinforce it so this doesn't happen again. The dealer was closed today (Monday) so I don't know if the parts will be covered under warranty or not, but they should be. This is an obvious design flaw.

RidingDonkeys

Husqvarna

Pro Class

IPA Brewer

Husqvarna

AA Class

IPA, was the metal bracket on? I've rallied the hell out of mine with the enduro engineering plate from day one. So far, so good....

Also, after breaking stuff in a crash, my dealer priced and ordered plastics. Had it at my door in 2 weeks.

Harder,

It was box stock. Good to hear the lead time is reasonable.

Thanks

I better go look just to make sure...

I better go look just to make sure...