-

Hi everyone,

As you all know, Coffee (Dean) passed away a couple of years ago. I am Dean's ex-wife's husband and happen to have spent my career in tech. Over the years, I occasionally helped Dean with various tech issues.

When he passed, I worked with his kids to gather the necessary credentials to keep this site running. Since then (and for however long they worked with Coffee), Woodschick and Dirtdame have been maintaining the site and covering the costs. Without their hard work and financial support, CafeHusky would have been lost.

Over the past couple of weeks, I’ve been working to migrate the site to a free cloud compute instance so that Woodschick and Dirtdame no longer have to fund it. At the same time, I’ve updated the site to a current version of XenForo (the discussion software it runs on). The previous version was outdated and no longer supported.

Unfortunately, the new software version doesn’t support importing the old site’s styles, so for now, you’ll see the XenForo default style. This may change over time.

Coffee didn’t document the work he did on the site, so I’ve been digging through the old setup to understand how everything was running. There may still be things I’ve missed. One known issue is that email functionality is not yet working on the new site, but I hope to resolve this over time.

Thanks for your patience and support!

You should upgrade or use an alternative browser.

How I will build my own oil cooler for my TE511

- Thread starter Rearwheelin

- Start date

Rearwheelin

Husqvarna

Pro Class

Rearwheelin

Husqvarna

Pro Class

I would think driving the centers out would weeken them ? I drove them out a little to coat them before using them so they are internally sealed.No, bad idea, please don't think that. Drive the centers out at least while the JB is still semi soft and seal with new JB.

Rearwheelin

Husqvarna

Pro Class

As soon as I do your breather mod and refill Rads . I might skip the breather mod and just fill rads lolWhen's test time?

Rearwheelin

Husqvarna

Pro Class

I don't think the rivets are under any stress at all. The JB alone is holding with 6,000+ lbs of strength . I think the clutch cover will break before the fitting breaks offThey don't add any strength, they are only there to form the buck-tail and those rivits don't have lock collars on the stems.

if anything the rivets helped the JB form a great bond. I will shave the rivets A little .

if anything the rivets helped the JB form a great bond. I will shave the rivets A little .Rearwheelin

Husqvarna

Pro Class

Or maybe a clutch plate inspection hole hahaThat is one sexy clutch cover, you got there

Hey, on the bright side, if it doesn't work, now you have a custom oil return for your oil breather...

Rearwheelin

Husqvarna

Pro Class

Rearwheelin

Husqvarna

Pro Class

Rearwheelin

Husqvarna

Pro Class

Rearwheelin

Husqvarna

Pro Class

Just spent $40 on a craftsman step bit , ouch ! Should of just bought one from you. Oh well it will last a long time and come in handy with my projects .When's test time?

McKay

Husqvarna

AA Class

Lol, no more grinding, you need the heads and tails for them to function. Vibration and heat cycles are what Im concerned with. Give it a shot but don't get too far from home or the truck and get them out ASAP when your done.

Rearwheelin

Husqvarna

Pro Class

The inner two I had to grind so they will clear the basket, I will leave the other alone . The two I grinded are in a low stress area the JB has a really good hold on the fitting. When you tap it sounds like the mod was poured with the original mold.Lol, no more grinding, you need the heads and tails for them to function. Vibration and heat cycles are what Im concerned with. Give it a shot but don't get too far from home or the truck and get them out ASAP when your done.

Rearwheelin

Husqvarna

Pro Class

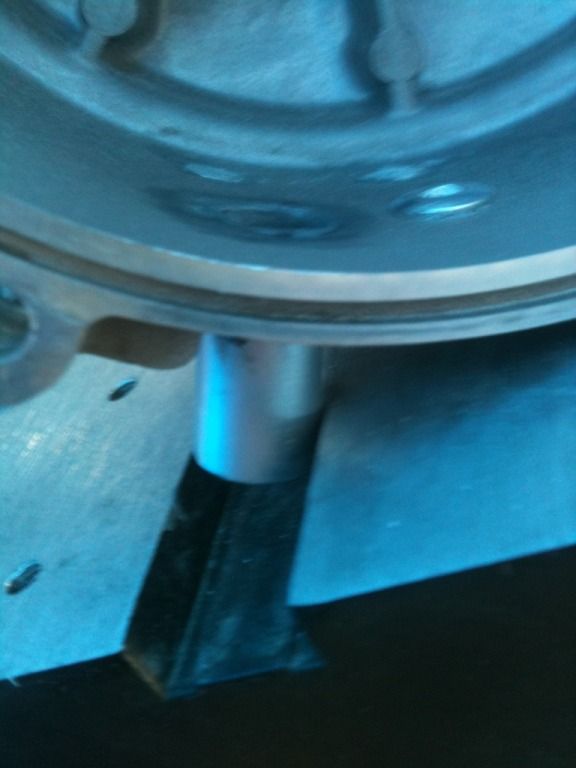

The cover is too thin. I would have .I might be a bit clueless but why not take a good solid piece of round stock, thread it, thread the hole in your cover, and thread it into the hole with some red loctite. Then, drill out the round stock and tap it for whatever barb fitting you're going to use.

Xcuvator

Husqvarna

Pro Class

I think you are doing it the best you can for a test.The cover is too thin. I would have .

I don't know how you will be able to tell if or how much flow you get through the cooler tubes? Do you have base oil temperatures for given ambient temps on a particular hill climb or hard ride with out the cooler? Or oil temps compared to coolant temps?

Just wondering.

Just wondering.Rearwheelin

Husqvarna

Pro Class

I will hook a clear tube to the hose barb and run it to the roof of my house to see what kind of pressure it puts outI think you are doing it the best you can for a test.

I don't know how you will be able to tell if or how much flow you get through the cooler tubes? Do you have base oil temperatures for given ambient temps on a particular hill climb or hard ride with out the cooler?Just wondering.

I will figure out a way to transfer the heat out of the oil after a pressure and flow test. Maybe pump the oil into the swing arm or frame .

I will figure out a way to transfer the heat out of the oil after a pressure and flow test. Maybe pump the oil into the swing arm or frame .

hee hee

hee hee