nev..

Terrarist

What is the new part? Pics?

+1 I'm intrigued. I tried replacing the broken piece with a short bit of fibreglass tent pole but couldn't get it the right length/shape to stop it from losing it's position.

As you all know, Coffee (Dean) passed away a couple of years ago. I am Dean's ex-wife's husband and happen to have spent my career in tech. Over the years, I occasionally helped Dean with various tech issues.

When he passed, I worked with his kids to gather the necessary credentials to keep this site running. Since then (and for however long they worked with Coffee), Woodschick and Dirtdame have been maintaining the site and covering the costs. Without their hard work and financial support, CafeHusky would have been lost.

Over the past couple of weeks, I’ve been working to migrate the site to a free cloud compute instance so that Woodschick and Dirtdame no longer have to fund it. At the same time, I’ve updated the site to a current version of XenForo (the discussion software it runs on). The previous version was outdated and no longer supported.

Unfortunately, the new software version doesn’t support importing the old site’s styles, so for now, you’ll see the XenForo default style. This may change over time.

Coffee didn’t document the work he did on the site, so I’ve been digging through the old setup to understand how everything was running. There may still be things I’ve missed. One known issue is that email functionality is not yet working on the new site, but I hope to resolve this over time.

Thanks for your patience and support!

What is the new part? Pics?

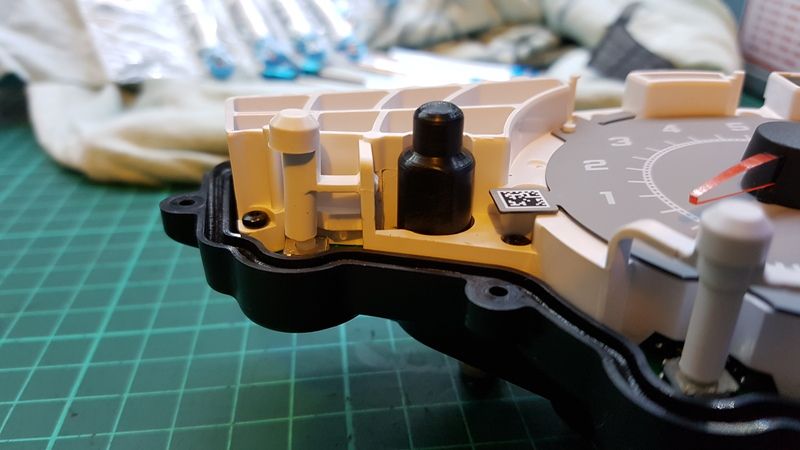

...So im making a new part on my CNC tonight

The new part i produced is working great, no gluing, just open and pull out the broken part and drop the new part in the hole and re-assemble!

Super easy and works 100 times better than the hard to press stock thing

What is the new part? Pics?

Joining the queue.

Some pics and and maybe a little "tutorial" would be great

Go & see Dave at First Class Motorcycles in Lilydale.Lookin forward to Monday when I can give Greg a call and discuss my running issues with my stock TR

I don't think the government will respond quick enough to the safety of the issue with stalling /having to give it a gut full at the lights while letting the clutch out to prevent stalling with a recall moss update

I'm thinking spoofing but this is the most positive post I have read regarding a true recent upgrade straight from the manufacturer

I'm in Albury and a ride up there would save me the cost and effort of installing a power commander

Thanks terrable for sharing your experience

Go & see Dave at First Class Motorcycles in Lilydale.

If anyone still decides on the place, I'm always up for a cuppa/ beer/vino...and only 15 mins away.

They're just as unlikely to hook up to "BMW Motorrad Germany" as the Canberra mob. It's sort of hard when the computers in Munich were switched off 2+ years ago

and no dealer/ service folks around the globe has had access to any BMW data ever since.

Hmmmm...

BECAUSE of that fact, Dave at First Class took THREE! months of trail and error (rather than electronic diagnostics) to find what had stranded my Strada. Yup, the good, old-fashioned piecemeal way, no fancy online-sessions possible.

Apart from the days I spent on the phone trying to find some way and/ or people to get this turd running again (it has, ever since...but who knows what's next? And when/ where?)

But hey, Lilydale is not a bad place, it's a launching pad for some great roads/ tracks in the nearby hills and it's got a couple of decent motels for an extended stay

If anyone still decides on the place, I'm always up for a cuppa/ beer/vino...and only 15 mins away.

Joining the queue.

Some pics and and maybe a little "tutorial" would be great

Yeah the designer of the original needs to be shot, i could design better in my sleep

I made it from delrin, its great to machine and withstands high temps it might get subjected to in the sun, flat bottom and rests on the button, the hole in the panel isnt round so needed to be shaped to suit.. weight would be no more than 10grams.

The M button dont get the use the S one does, i did look at replacing it but though ive used it once since buying the bike so did see the point in wasting time/effort on it lol

Hi SusserfGo & see Dave at First Class Motorcycles in Lilydale.

Thanks for the info.

Using Delrin/POM in my workshop everyday, so I'm familiar with its properties.

True about the M-button...should (maybe) last the life of the bike.

Weight could become a concern as even 10g multiplied by the thumping on gravel/ dirt could conceivably become a stress over a period of time to destroy the actual

switch-button (as there must be a spring in that to return the button to its "disengaged" position).

Some sort of "suspended" arrangement wouldn't apply permanent stress/ strain on the switch-button (similar to the original set-up).

Again, just thinking aloud...as I've been mulling over this issue for a couple of years now, trying to see all angles, valid or not.

I repaired my S button for the 3rd time today.

...I wonder if a solution like the 10g part which Hulksta made, which had a couple of mm of sponge on the bottom (to spread the load and keep the weight of the part off the switch might do the trick.