AUSKY

Husqvarna

AA Class

I thought that it’d be wicked if I could put an auto clutch in my 2000 WR360 as the clutch pull was quite heavy & it would just top off such a great bike. I was warned against using the Recluse EXP as the torque of the 360 was too much for the EXP so after making enquires about the Relcuse Z Start Pro I was told that they would fit my bike, so I ordered one & went to install it. Unfortunately this was not the case, due to the 360 only having 7 clutch plates & the Recluse using 8 plates & the Recluses pressure plate not engaging the 360’s basket enough for my liking. As this model Recluse Z Start Pro (RMS-856) is good for other Huskies, the 360 project was shelved & it went into my 08 TE510 instead. Until now.

A friend had me install a 6 speed from another 360 into his 09 WR300 & while it was apart I tried the 300 basket in the 360 but soon realised the primary drive on the crank would need to be changed as well as the water pump gear & the power valve gear as well & that was getting in the too hard basket. The ring gear/clutch bearing of the 09 300 is one piece & the 360’s was 2 piece which wouldn’t allow it to be separated.

The primary drive of the 360 is 25/60 where the primary drive of the 250/300 is 27/69 & this is common for all of these models. This got me thinking that the only thing that we really needed was the 360 primary drive & a basket capable of holding 8 plates (250), that would fit into the 360 clutch housing & assemble them together. I happened to come across a 1999 WR250 clutch basket (Part No 8001 86863), which is a 2 piece ring gear/clutch bearing setup & in excellent condition & I thought it might be suitable, so I snapped it up hoping that the ring gears were able to be swapped out.

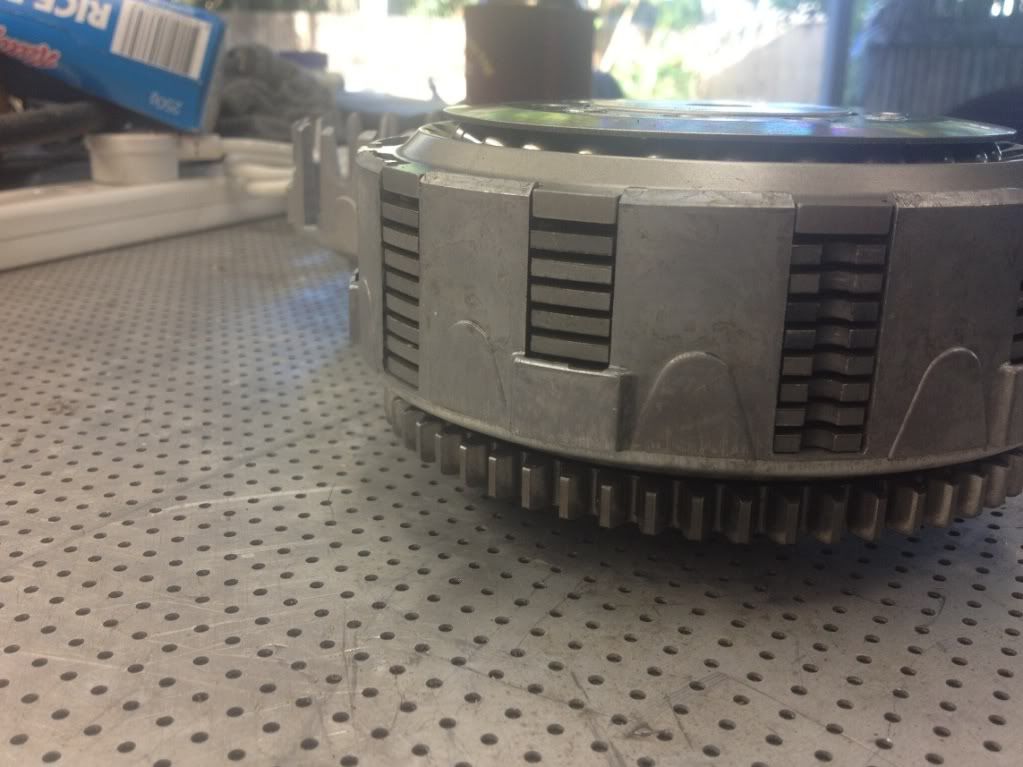

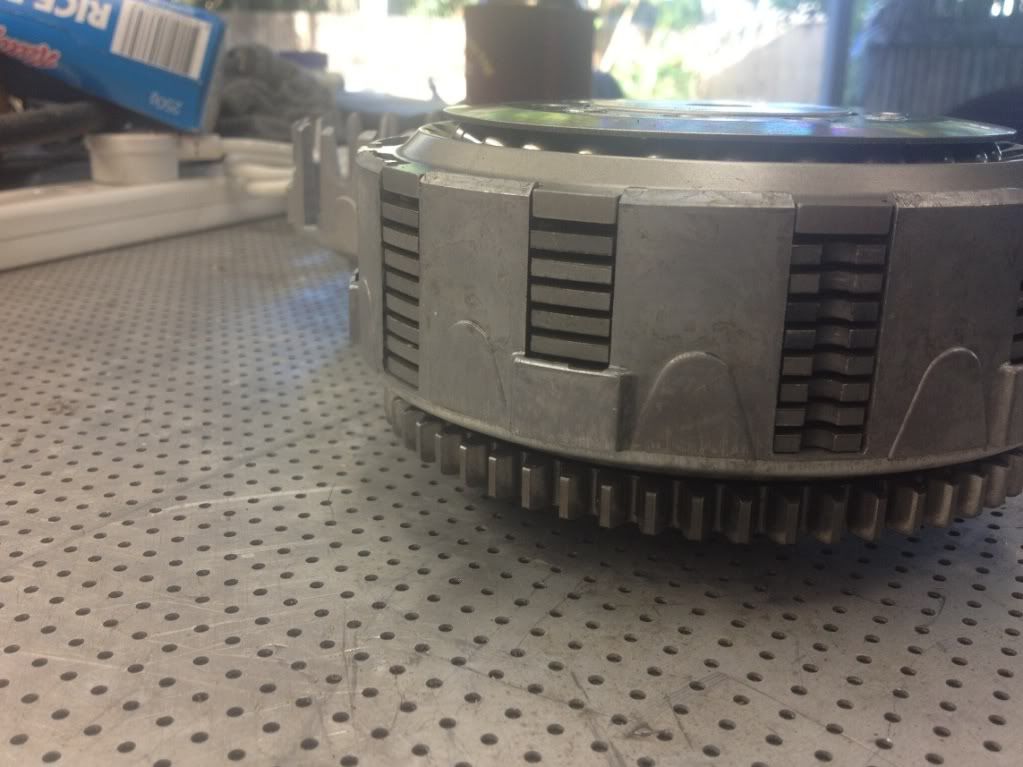

I first checked the Recluse in the 250 basket & all was good for the 8 plates & the height was good for the Clutch housing.

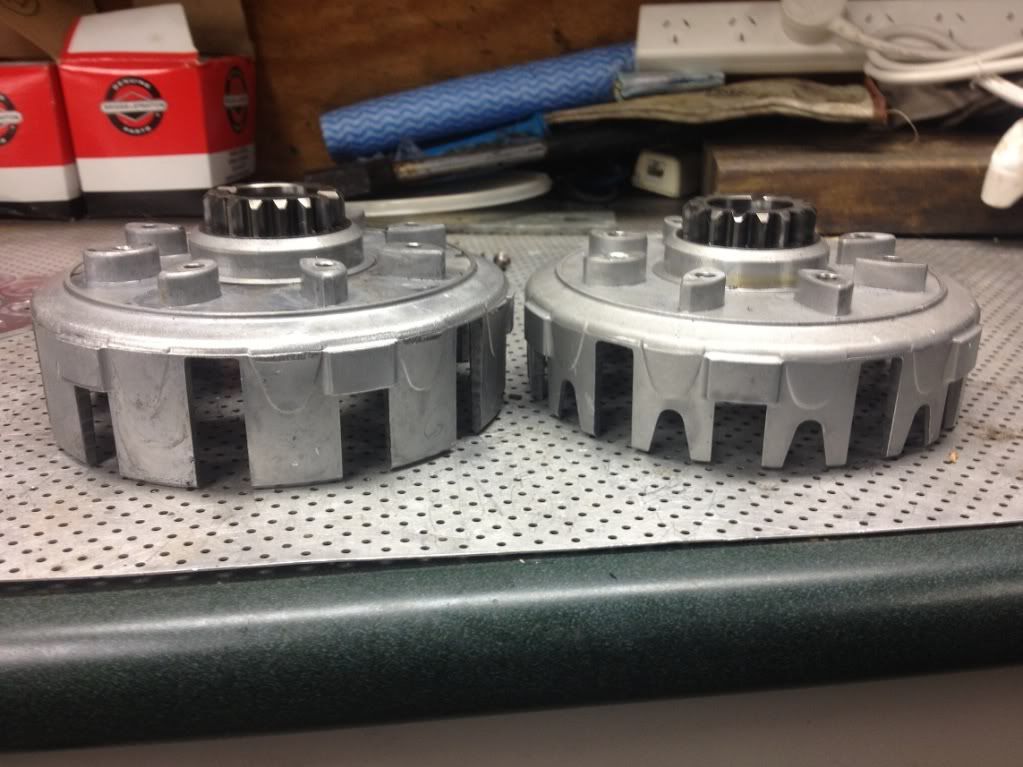

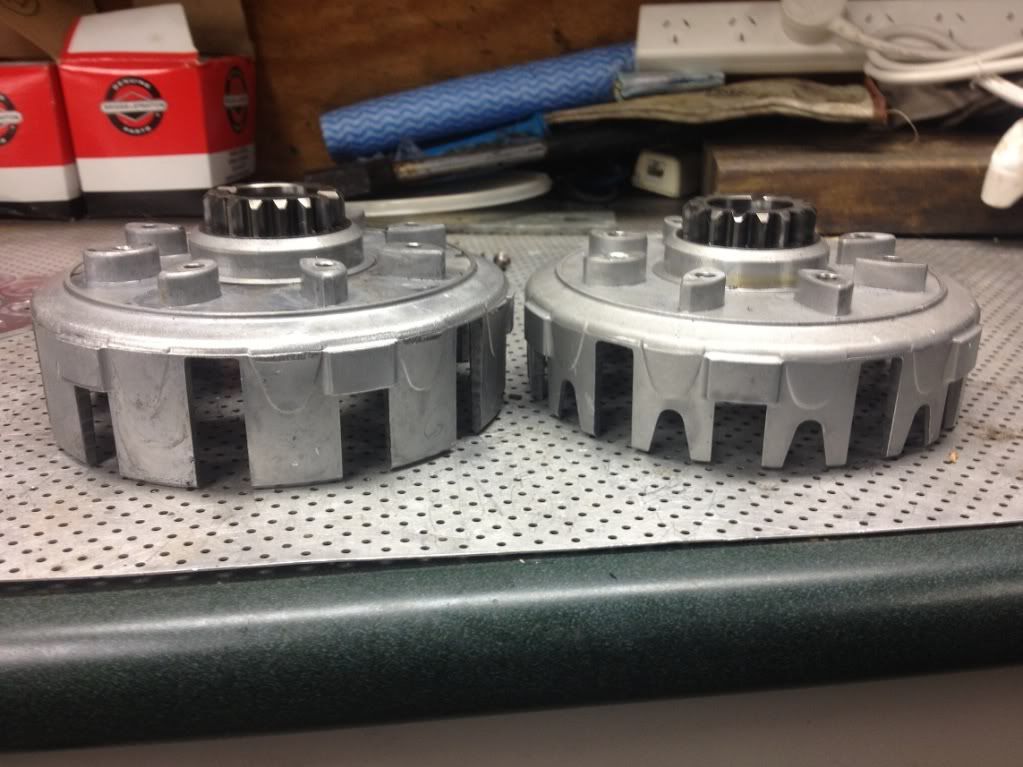

So I drilled out the rivets of both baskets

& was happy with what I saw

The ring gears were the same internal dimensions but just had different numbers of teeth.

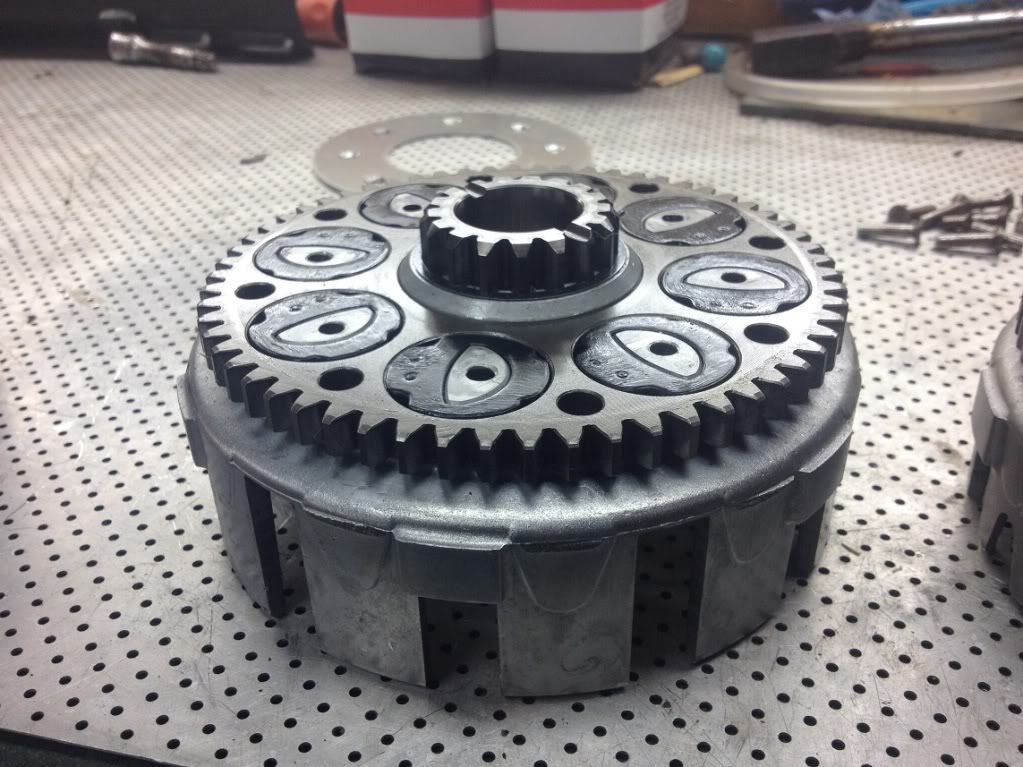

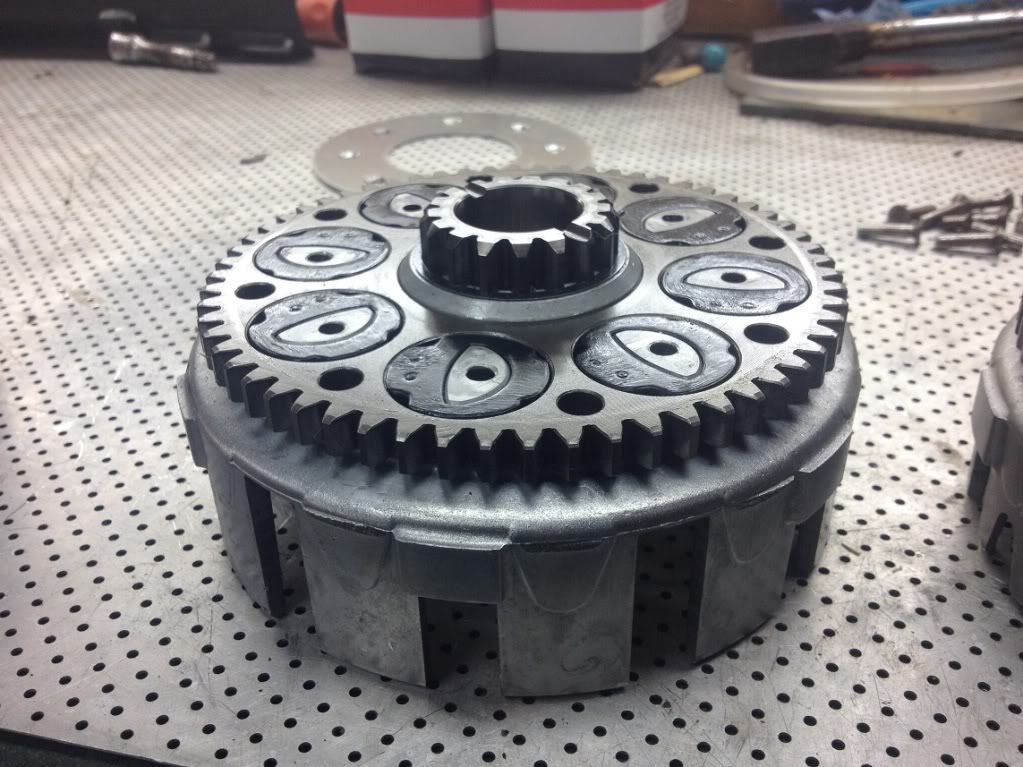

I installed the 360 ring gear on the 250 basket, reinstalled the backing plate & riveted it all back together.

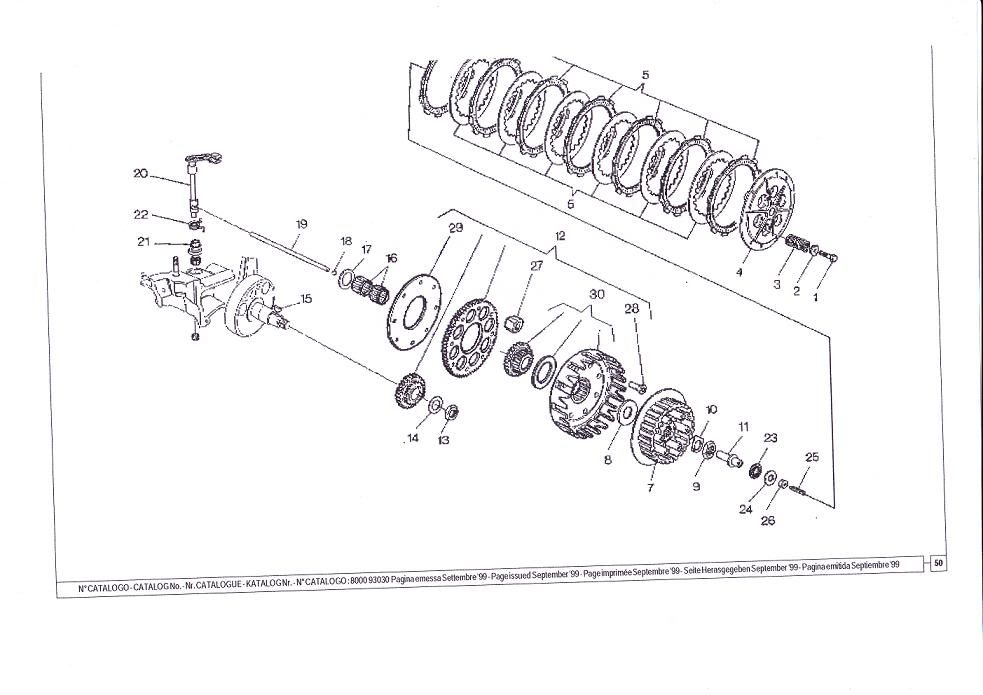

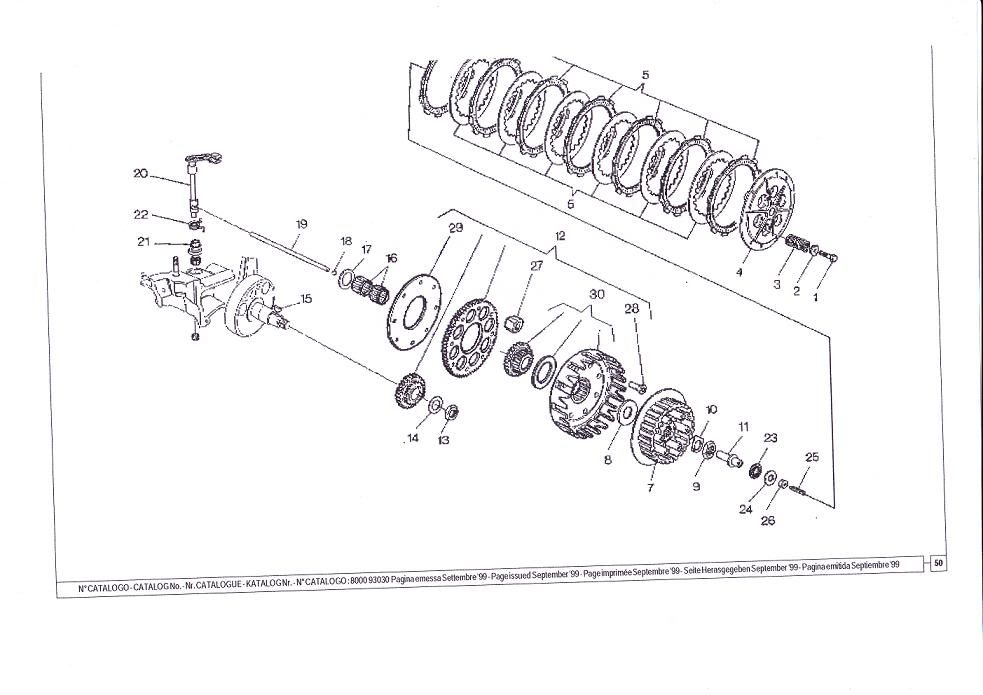

The shim that the clutch bearings sit on (No17 in exploded diagram) had to be replaced with a thinner shimming washer as the clutch basket spacer washer (No8) was touching the clutch basket & locking it up.

After replacing this shim (No17) the clutch was free of the spacer washer (No8). The rest of the Recluse went in as per the installation guidelines & the 360 throw out bearing was used together with the WR250 Recluse spacer.

The throw out had to have the screw turned in by about 4 mm for the extra clutch plate & steel & to allow the correct free play at the clutch lever on the bars.

When I went to install the clutch cover the casting for the sight glass was just touching the top of the Recluse top plate, so after grounding a bit out of it for clearance I realised it would be better to use a spacer plate.

I had some 2.5mm aluminium sheet lying around in the workshop, so I put a gasket on it, traced around it, cut it out & sandwiched it in between the cover & the housing with a gasket either side & it is barely noticeable.

I tried a few different spring/ball combinations before settling on what Recluse recommended for the WR250 2 Stroke – C200L5 & C150M3 with 24 steel balls & 3 Tungsten ones. This allows a hard engagement with medium revs, just the way I like it. For a bit smoother engagement I might remove the 3 Tungsten balls. Maybe

The clutch feel is super light, like my 125, when I have to use it & the 360 clutch basket rattle has gone. I couldn’t be happier with the big girl now. It has been a mission to get this project to where it is now but well worth it so I thought I'd share it with you all.

A friend had me install a 6 speed from another 360 into his 09 WR300 & while it was apart I tried the 300 basket in the 360 but soon realised the primary drive on the crank would need to be changed as well as the water pump gear & the power valve gear as well & that was getting in the too hard basket. The ring gear/clutch bearing of the 09 300 is one piece & the 360’s was 2 piece which wouldn’t allow it to be separated.

The primary drive of the 360 is 25/60 where the primary drive of the 250/300 is 27/69 & this is common for all of these models. This got me thinking that the only thing that we really needed was the 360 primary drive & a basket capable of holding 8 plates (250), that would fit into the 360 clutch housing & assemble them together. I happened to come across a 1999 WR250 clutch basket (Part No 8001 86863), which is a 2 piece ring gear/clutch bearing setup & in excellent condition & I thought it might be suitable, so I snapped it up hoping that the ring gears were able to be swapped out.

I first checked the Recluse in the 250 basket & all was good for the 8 plates & the height was good for the Clutch housing.

So I drilled out the rivets of both baskets

& was happy with what I saw

The ring gears were the same internal dimensions but just had different numbers of teeth.

I installed the 360 ring gear on the 250 basket, reinstalled the backing plate & riveted it all back together.

The shim that the clutch bearings sit on (No17 in exploded diagram) had to be replaced with a thinner shimming washer as the clutch basket spacer washer (No8) was touching the clutch basket & locking it up.

After replacing this shim (No17) the clutch was free of the spacer washer (No8). The rest of the Recluse went in as per the installation guidelines & the 360 throw out bearing was used together with the WR250 Recluse spacer.

The throw out had to have the screw turned in by about 4 mm for the extra clutch plate & steel & to allow the correct free play at the clutch lever on the bars.

When I went to install the clutch cover the casting for the sight glass was just touching the top of the Recluse top plate, so after grounding a bit out of it for clearance I realised it would be better to use a spacer plate.

I had some 2.5mm aluminium sheet lying around in the workshop, so I put a gasket on it, traced around it, cut it out & sandwiched it in between the cover & the housing with a gasket either side & it is barely noticeable.

I tried a few different spring/ball combinations before settling on what Recluse recommended for the WR250 2 Stroke – C200L5 & C150M3 with 24 steel balls & 3 Tungsten ones. This allows a hard engagement with medium revs, just the way I like it. For a bit smoother engagement I might remove the 3 Tungsten balls. Maybe

The clutch feel is super light, like my 125, when I have to use it & the 360 clutch basket rattle has gone. I couldn’t be happier with the big girl now. It has been a mission to get this project to where it is now but well worth it so I thought I'd share it with you all.

Great work and how does it feel riding that beast 360 with this clutch installed?

Great work and how does it feel riding that beast 360 with this clutch installed?