Bike: TE 450 ’08 with only 13 hours on the meter.

Tank insert threads lubricated after every wash and the bolts gently tightened

Two tank inserts started to spin when I tried to disassemble the bolts for lubrication.

Inserts removed with a drill (spin and pull until insert comes out of the tank)

The threads looked just fine. The problem seems to be the material combination brass and steel. The alignment surfaces seem to easily get stuck to each other.

Solution:

Hole after removal of insert had a diameter of approx. 9mm.

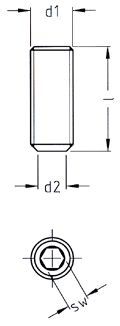

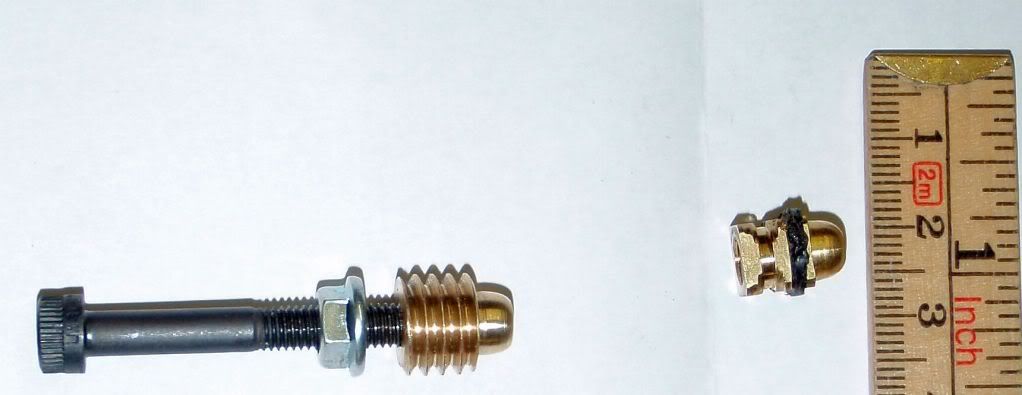

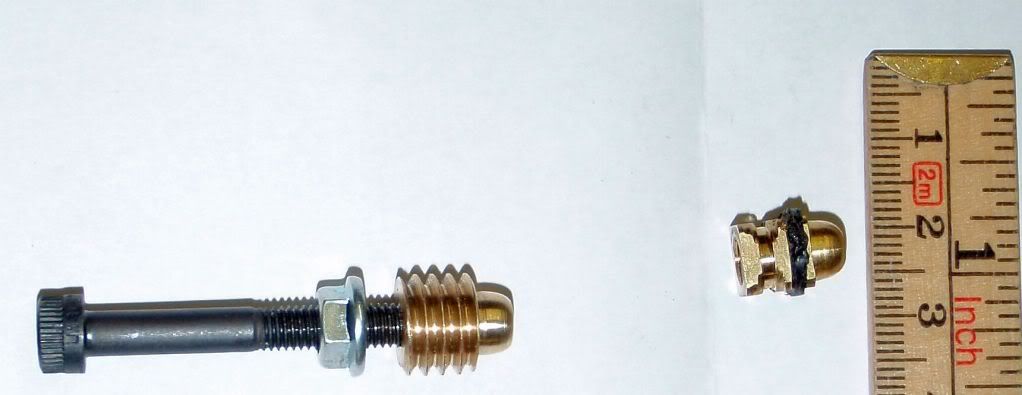

A new insert was made with a suitable outer thread with a outer diameter of approx. 11mm (UNC 7/16-14) and the M5-iso inside. The old insert to the right.

The hole and new insert were cleaned and rubber reinforced glue were added.

A bolt and lock nut was used for the assembly

A drill was used for the tank assembly in order to get a proper alignment

Drill removed, use a wrench an a allen key to unlock an disassemble bolt.

All done! If the insert starts to spin it will now come out of the tank and could be reused.

Tank insert threads lubricated after every wash and the bolts gently tightened

Two tank inserts started to spin when I tried to disassemble the bolts for lubrication.

Inserts removed with a drill (spin and pull until insert comes out of the tank)

The threads looked just fine. The problem seems to be the material combination brass and steel. The alignment surfaces seem to easily get stuck to each other.

Solution:

Hole after removal of insert had a diameter of approx. 9mm.

A new insert was made with a suitable outer thread with a outer diameter of approx. 11mm (UNC 7/16-14) and the M5-iso inside. The old insert to the right.

The hole and new insert were cleaned and rubber reinforced glue were added.

A bolt and lock nut was used for the assembly

A drill was used for the tank assembly in order to get a proper alignment

Drill removed, use a wrench an a allen key to unlock an disassemble bolt.

All done! If the insert starts to spin it will now come out of the tank and could be reused.