Look there is a proper way of doing things and the other ways of doing the same things, which there are many.

Oh! and what "Busted RS" said above is true. No math calculation is needed to use an adaptor at 90 degrees. I've been an FAA licensed Airframe and Powerplant technician since 1991. Adding the torque adaptor at 90 degrees to the torque wrench adds no length to the wrench itself.

I thought those of us who selected the quality in Husqvarna products were a step up from the rest and maintained them with the same quality work to do maintenance.

Rather than categorizing any of us like some half assed kids who buy a worn out Japanese bike used and beat to death and let it go to shit.

Never doing anything to it properly. Maybe I'm wrong.

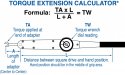

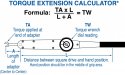

What is torque?

Basic Torque Formula

L (length) x F (force) = T (torque)

Example: A two foot lever at a right angle to the fastener with 200 pounds at the end will produce 400 foot/pounds of torque.

Torque Formula: L x F = T

According to Webster:

- A twisting or wrenching effect, or moment, exerted by a force acting at a distance on a body, equal to the force multiplied by the perpendicular distance between the line of action of the force, and the center of rotation at which it is exerted.

- A force, which tends to produce rotation. The measurement of torque is based on the fundamental law of the lever.

What are we trying to achieve with a torque wrench?

Answer: Proper Clamping Force

- Torque is expressed in commonly used units of measurement such as:

- in. lbs. = inch pounds

- in. ozs. = inch ounces

- ft. lbs. = foot pounds

- Nm = Newton meter

- cNm = Centi Newton meter

Torque and Clamping Force

Controlling the torque applied in tightening threaded fasteners is the most commonly used method for the application of clamping force. There are many factors which may affect the relationship between torque and clamping force of threaded fasteners. Some of these are: the type of lubricant used on the threads, the material from which the bolt and nut are made, the type of washers used, the class and finish of threads and various other factors. It is not possible to establish a definite relationship between torque and clamping force which will be applicable for all conditions.

Torque Versus Clamping Force Only a small part of the torque applied to a fastener contributes to clamping force. The remaining, as much as 90% of the total applied torque, is used to overcome friction under the fastener head (or between nut and washer) and friction in thread engagement.

TORQUE

Head Friction:

45% - 55%

Thread Friction:

35% - 45%

Clamping Force:

10%

TORQUE

1. Head Friction

2. Thread Friction

3. Clamping Force

Oh and it goes with out saying using the proper lube with all fasteners when torqueing any and all fasteners is a must to get any consistent readings when building an engine.

Why Use ARP Ultra-Torque Fastener Assembly Lubricant

Why Use ARP Ultra-Torque Fastener Assembly Lubricant

arpfasteners

arpfasteners

) on torque adaptors and the reality is many may consider these once off and see as a waste of money... but in my case they are hard to find and particularly $$ in this country and need to fashion one out due to necessity.

) on torque adaptors and the reality is many may consider these once off and see as a waste of money... but in my case they are hard to find and particularly $$ in this country and need to fashion one out due to necessity. . Anyway, l would always harden modified nut before l use for any application like a cylinder nut.

. Anyway, l would always harden modified nut before l use for any application like a cylinder nut.