Depowering the BMS-E and twisting the throttle does not reset the ECU or adaptions, that is an urban myth, it applied only to some early ECU's from the 1990's, on these systems you can only reset adaptions via diagnostics command. The idle until fan kicks in is correct to rebuild the tables after a reset thoughdid the rest on the eco (disconnect battery, wait 30 minutes, throttle open close 3X, then off and on, then idle until the fan kicks on). It seem ok now.

-

Hi everyone,

As you all know, Coffee (Dean) passed away a couple of years ago. I am Dean's ex-wife's husband and happen to have spent my career in tech. Over the years, I occasionally helped Dean with various tech issues.

When he passed, I worked with his kids to gather the necessary credentials to keep this site running. Since then (and for however long they worked with Coffee), Woodschick and Dirtdame have been maintaining the site and covering the costs. Without their hard work and financial support, CafeHusky would have been lost.

Over the past couple of weeks, I’ve been working to migrate the site to a free cloud compute instance so that Woodschick and Dirtdame no longer have to fund it. At the same time, I’ve updated the site to a current version of XenForo (the discussion software it runs on). The previous version was outdated and no longer supported.

Unfortunately, the new software version doesn’t support importing the old site’s styles, so for now, you’ll see the XenForo default style. This may change over time.

Coffee didn’t document the work he did on the site, so I’ve been digging through the old setup to understand how everything was running. There may still be things I’ve missed. One known issue is that email functionality is not yet working on the new site, but I hope to resolve this over time.

Thanks for your patience and support!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Power Commander V + Autotune install

- Thread starter chris1261

- Start date

Twisting the throttle resets all BMW/Husky 449-2006-2014 ecu's... Just sayin.

Not on the programmable ECU's in the Terra and Nuda, I looked at the other Husky's made during BMW ownership like the BMW 450/510 TE/SM as there was a question asked here as to if/when Hexcode would support them with the GS911 and the ECU's are not to the BMW spec of how they do things, the 450/510 in particular uses a Mikuni ECU rather than the Keihin on the BMW G450X and uses odd/simplistic looking iBeat diagnostics software

danketchpel

Husqvarna

AA Class

I called Dynojet today.

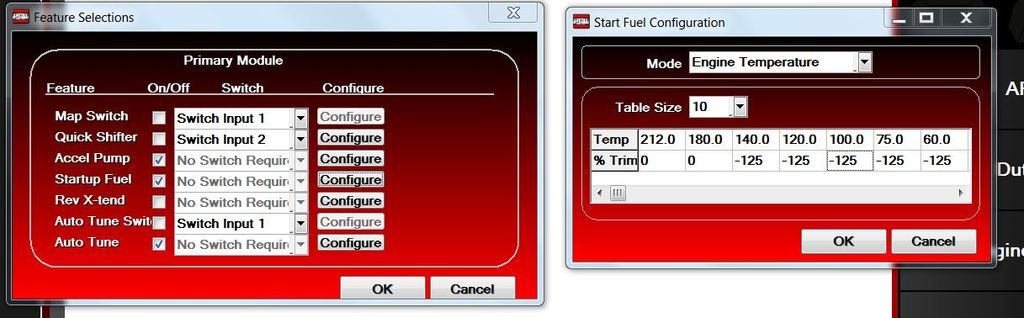

There is a startup fuel option under "tools/configure/configure/feature/startup fuel". He suggested setting the number of engine revs (the time out function) to 25 and -10% fuel as a starting point.

I've worked with this feature in the past. The thing about this feature is that it affects both cold and hot startup. But it might be worth going back and trying it again armed with the new info. I think I might limit revolutions to say 10 or less this time and try something like -50%, it's trial and error to balance cold/hot start requirements.

I asked about how the PC acts during cranking. If the start up fuel feature is not enabled then the PC does nothing to the fuel mapping until the engine is actually running. It relies on the original ECU mapping for startup mapping, cold or hot. If the cold start feature is enabled then it will come into play immediately upon cranking the engine and use the settings in the cold start option until it times out by engine revolutions.

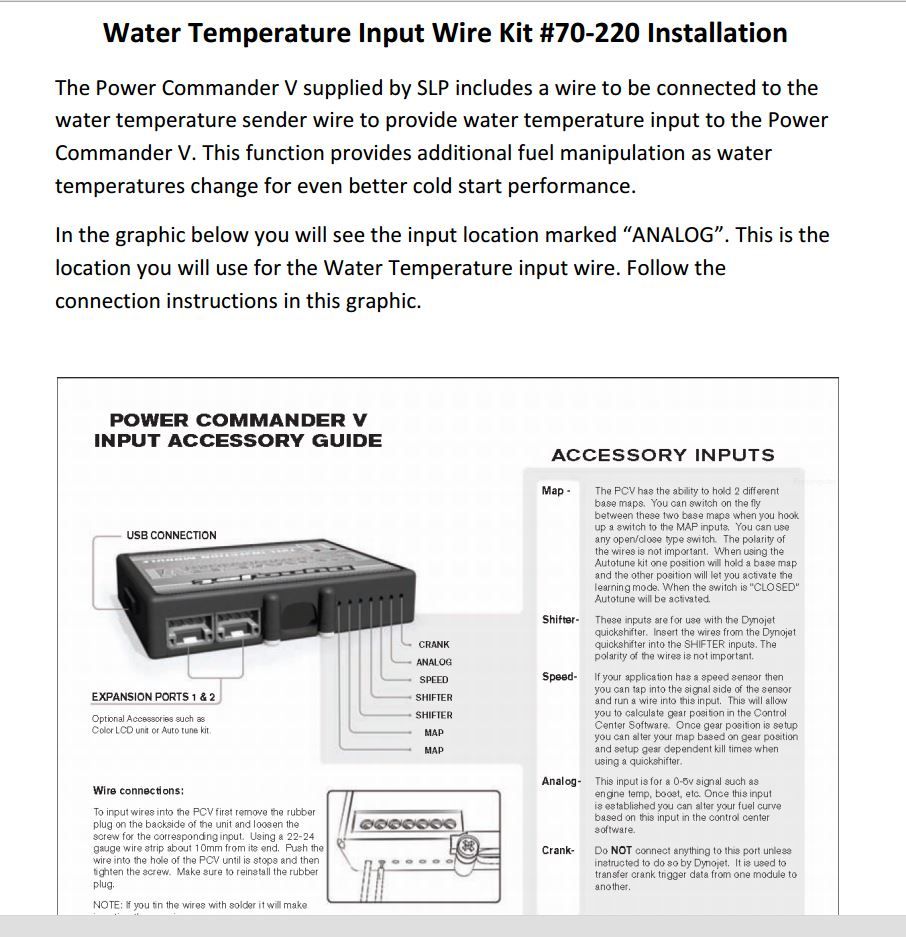

The other option is if you connect a temp sender to the PC (using the analog data port) and correctly calibrate the voltage vs temp for the sender (0-5v), then create a cold start table varying fuel against engine temp you can have a cold start only map which does not affect hot start. I think this is the ultimate solution and may very well be worth the effort. Really the only effort is calibrating the stock temp sender and tapping the wire to connect to the PC. I have figured out which wire it is but need to find a clean place to tap into it. I don't think there is a way to time out the map with engine revs or time so you'd need to have a very steep temp ramp in the map.

Here's some basic info on the available connections to a PC5.

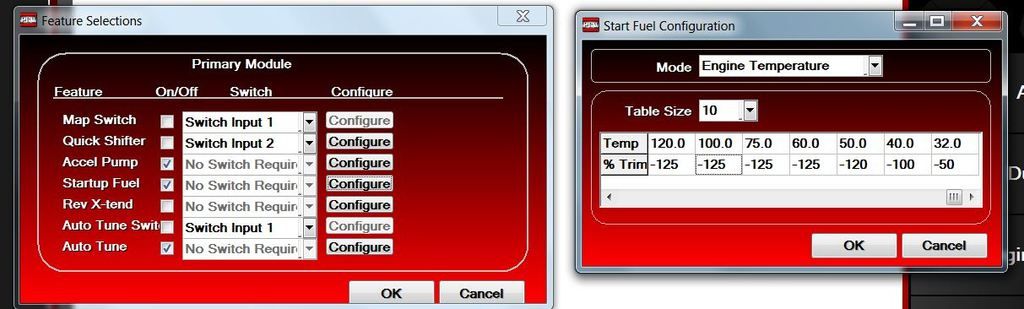

I finally got around to implementing this to solve my cold start problem.

And yes it worked!!!

The first step was to tap into the engine temp sender signal. I decided the easiest place to do this was right at the sender connector (the sender is on the right side just in front of the spark plug). I pulled back the large rubber boot and there are 2 wires there, the purple wire is the "hot" signal and the gray/white is the ground. I carefully stripped off a small amount of insulation and soldered on my connection wire which I ran out the boot and back to the PC5. I connected it to the analog input port. If you do this carefully you can't even see the wire.

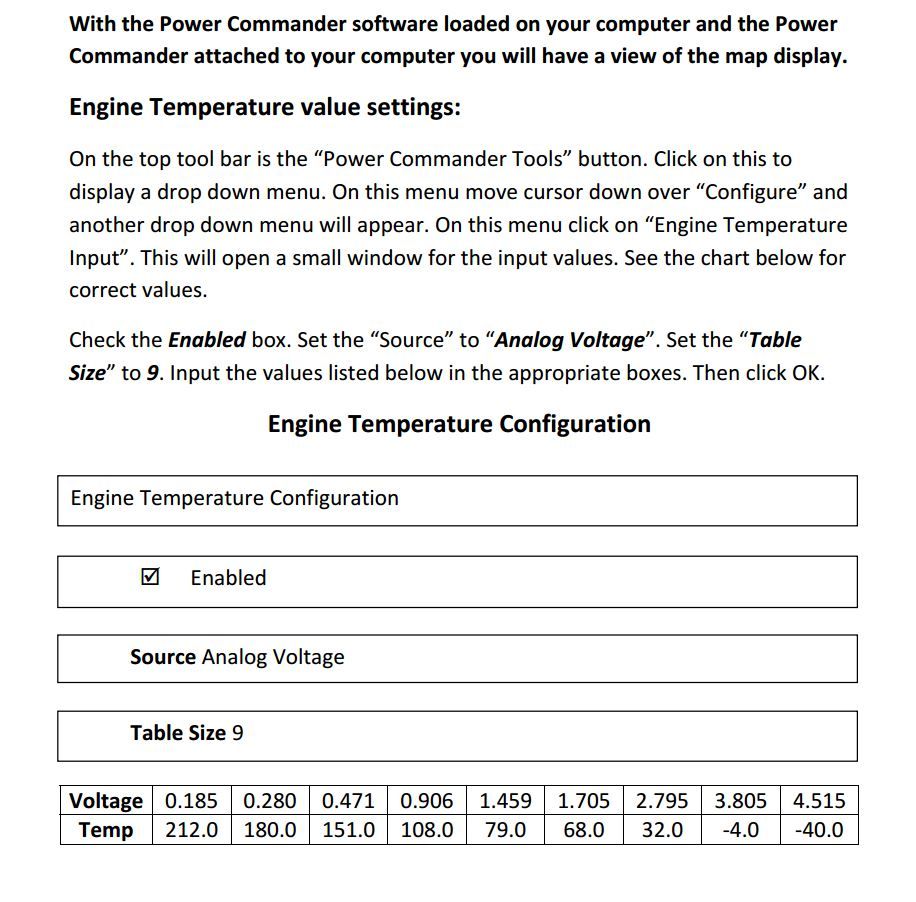

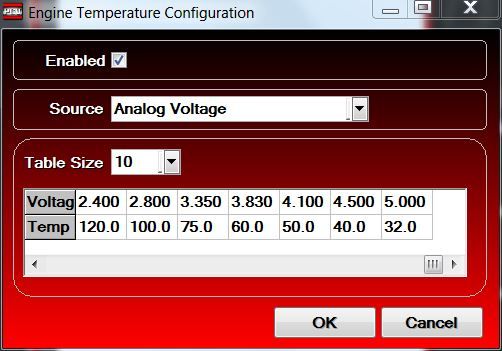

After I had it connected I had to calibrate the signal. DO NOT use the values in the document above, they are for a different bike and completely wrong for the Husky.

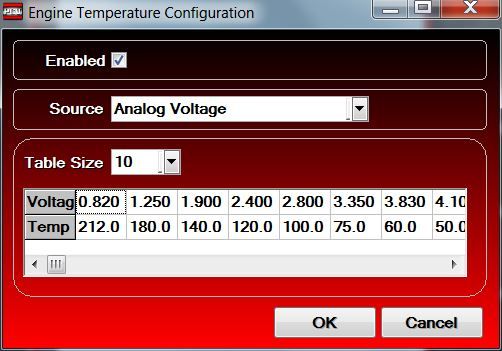

I did this calibration using an IR temp gun (aimed at the cylinder head next to the temp sender) and a digital volt meter. I started at "cold" ambient temperature (~60 degrees) and with the power turned on measured the voltage between the purple wire and ground and took a reading. I then started the bike and took voltage readings every 20 degrees of temperature rise and recorded them. It's not a linear curve, it's logarithmic curve. I did have to extrapolate the colder temps.

After that I created a table size of 10 temp/voltage table in the PC5. You can't display the entire range so I had to take 2 screen shots. I think in practice the table size could be much smaller for this application, probably 6 would work fine.

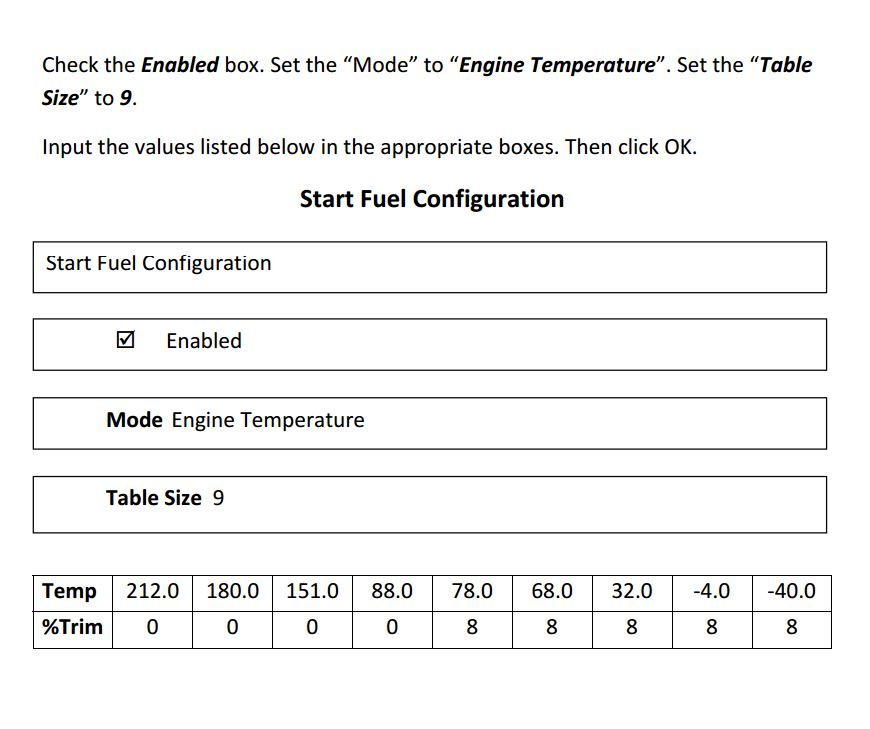

After that I was able to enable the cold start feature using engine temp as now the PC5 knows what temp the engine is at.

I knew the basic problem was far too much fuel being dumped into the engine at cranking speed, but only at colder temps. Above a basic warm up it wasn't an issue. Based on my taking the temp readings I figured that basic warm up cut-off was around 130-140 degrees. So basically I took away a massive amount of fuel in the cold range and left everything above 140 degrees unchanged.

My cold starts are now quite reliable without having to touch the throttle. I've tried them over about as wide a range as I can manage given the current weather in SoCal. I'm sorry but I don't plan to test it in freezing temps.

A couple observations.

1. The radiator fan kicks on at 230 degrees and kicks off at 218 degrees.

2. I think the thermostat opens around 190-200 degrees.

I apologize for not taking pictures during the wire installation. I can take some photos if anybody is interested in duplicating this. The nice thing about it is it's extremely low cost and not very hard to do.

Cyntax

Husqvarna

A Class

So I've been riding around with the PCV + Autotune installed for a wile now and I have accepted the trims 3 times after a long ride, this is how my map looks like at the moment, I have the feeling that I should adjust my AFR table but I have no idea where to start. Could any of you help me out a bit with this?

AFR Table:

MAP Table:

AFR Table:

MAP Table:

mag00

Husqvarna

Pro Class

A couple observations.

1. The radiator fan kicks on at 230 degrees and kicks off at 218 degrees.

2. I think the thermostat opens around 190-200 degrees.

This is of important note. How can the radiator liquid at 230 cool an engine to 200 degrees? What is the optimum constant temp the motor should run at?

This is one of the points I have been making all along. No amount of open thermostat can compensate for that. The fan kicks on late, and I don't know if the moss system or the new oss could reset the temp to when the fan kicks in. To compensate, the aux fan where the canister was is a remedy.

Baddrapp

Husqvarna

AA Class

The coolant, Zip Ty waterless, flows alot more with the thermostat delete. The only reason cars run so warm with fuel injection is for emissions. The higher temps help with the burn off. That's all it does. Fuel injection is just a fancy carburetor. That is why the ecu's are being locked. They don't want people changing, timing, amount of fuel, well all the parameters for better performance.

Tinken

Husqvarna

Pro Class

The flow is huge, so the transfer of heat from the cylinder to the heat exchanger is really improved. Even with a fully open thermostat, the flow restriction is ridiculous. Your fan hardly turns on because your engine runs a lot cooler, probably closer to 200 degrees. The only time I saw it come on was when you were sitting still for a long period of time. I'm suprised that Mag doesn't run a thermos-delete since he helped me design the thing in the first place.The coolant, Zip Ty waterless, flows alot more with the thermostat delete.

Oregoner

Husqvarna

AA Class

How does the thermo delete affect oil temps in a cool ambient? The thing is you WANT your oil temps to come up ASAP. If it doesn't it'll retain products of combustion ie condensation - not good. Who's measured oil temps vs ambient temps? How about a short daily commute in a cool ambient?

Baddrapp

Husqvarna

AA Class

Temperature indicator on the dash appears to warm up just as fast as before. It is about one or two bars below when at full temp. I deally you want oil temps between 180 - 220. But its a fine line, anything above 220 starts degrading the oil. Easy to check just throw a temp.guage in the oil sump.

Tinken

Husqvarna

Pro Class

The delete doesn't effect that, but the waterless coolant will. Water stores energy, but it takes longer to absorb and release it. Waterless coolant on the other hand, absorbs and releases energy quickly. Waterless coolant comes up to operating temperature much faster than with water.How does the thermo delete affect oil temps in a cool ambient? The thing is you WANT your oil temps to come up ASAP

danketchpel

Husqvarna

AA Class

These readings were taking with the bike stationary idling the whole time.This is of important note. How can the radiator liquid at 230 cool an engine to 200 degrees? What is the optimum constant temp the motor should run at?

This is one of the points I have been making all along. No amount of open thermostat can compensate for that. The fan kicks on late, and I don't know if the moss system or the new oss could reset the temp to when the fan kicks in. To compensate, the aux fan where the canister was is a remedy.

When the fan kicks on the coolant starts to cool down, along with the engine temp. This is normal operation for a liquid cooled engine.

There's a lot of debate about what the optimum temp should be and it probably varies depending on what you are trying to achieve. In reality the temps only get up to the point where the fan kicks on during extended idling or very very slow riding in hot weather. The rest of the time my bike stays below that, closer to what I'd estimate to be 190-210 which is pretty typical for many engines, actually a bit cooler than most car engines run.

I don't see much of an issue, especially running the XF2 coolant and full synth oil. Full synth oil won't start to break down until you get way hotter than that, maybe 100+ degrees above.

"Conventional oils will tolerate engine oil sump temperatures of up to 250 to as much as 275 degrees F without difficulty. According to Quaker State engineer Mark Farner, oils like Quaker State's full synthetics can easily withstand sump temperatures in excess of 300 degrees F, and he says that some oval track race teams are experimenting with temperatures as high as 350 degrees F. For a typical wet-sump engine, 300 degrees F is still extremely hot, but Farner says that synthetics, because of their molecular makeup, are better suited to withstand these temperatures. The downside is that additive packages do tend to break down faster in high-temperature environments, so if you plan on running oil temperatures in excess of 300 degrees, this would mean changing the oil after every track event regardless of the mileage."

danketchpel

Husqvarna

AA Class

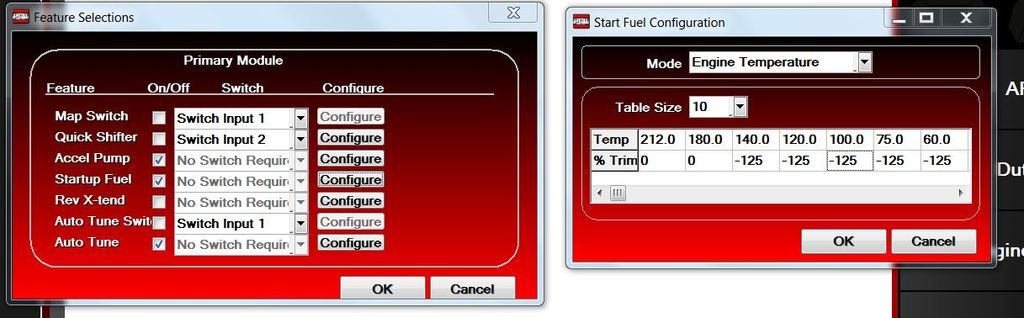

One thing to note. On the features selections window below where accel pump, startup fuel, map switch, Autotune, etc is. Only two of these can remain on at the same time.

I called Dynojet tech support to better understand this.

Their answer was there is no limit on features enabled, only on what inputs to the unit you can have. But as I had it in this case it will work. You can hook up a open/close switch to enable/disable the AT unit on the fly using the map input ports also.

I have since turned off AutoTune as I have been experimenting with how it feels/runs with it off vs with it on.

mag00

Husqvarna

Pro Class

The delete doesn't effect that, but the waterless coolant will. Water stores energy, but it takes longer to absorb and release it. Waterless coolant on the other hand, absorbs and releases energy quickly. Waterless coolant comes up to operating temperature much faster than with water.

You are mistaken. Please read. http://www.lytron.com/Tools-and-Tec...-Best-Heat-Transfer-Fluids-for-Liquid-Cooling

And here is a chart that may help

http://www.engineeringtoolbox.com/specific-heat-fluids-d_151.html

The waterless coolant is a good product with benefits that water based coolants can't offer, but heat transfer is not one of those benefits.

Of the benefits is the non corrosion properties, and the non boiling over/expansion properties.

mag00

Husqvarna

Pro Class

These readings were taking with the bike stationary idling the whole time.

When the fan kicks on the coolant starts to cool down, along with the engine temp. This is normal operation for a liquid cooled engine.

There's a lot of debate about what the optimum temp should be and it probably varies depending on what you are trying to achieve. In reality the temps only get up to the point where the fan kicks on during extended idling or very very slow riding in hot weather. The rest of the time my bike stays below that, closer to what I'd estimate to be 190-210 which is pretty typical for many engines, actually a bit cooler than most car engines run.

I don't see much of an issue, especially running the XF2 coolant and full synth oil. Full synth oil won't start to break down until you get way hotter than that, maybe 100+ degrees above.

"Conventional oils will tolerate engine oil sump temperatures of up to 250 to as much as 275 degrees F without difficulty. According to Quaker State engineer Mark Farner, oils like Quaker State's full synthetics can easily withstand sump temperatures in excess of 300 degrees F, and he says that some oval track race teams are experimenting with temperatures as high as 350 degrees F. For a typical wet-sump engine, 300 degrees F is still extremely hot, but Farner says that synthetics, because of their molecular makeup, are better suited to withstand these temperatures. The downside is that additive packages do tend to break down faster in high-temperature environments, so if you plan on running oil temperatures in excess of 300 degrees, this would mean changing the oil after every track event regardless of the mileage."

My fan only comes on when air is not flowing as it should be. Traffic or slow trail work. It should come on sooner, before the engine temp starts to rise.

Problem with all the varying temps is the ecu has to constantly adjust for that. Are you getting the most efficient/best power return when the fueling is constantly changing?

If you are looking for power, you probably want the cooler running engine.

danketchpel

Husqvarna

AA Class

My fan only comes on when air is not flowing as it should be. Traffic or slow trail work. It should come on sooner, before the engine temp starts to rise.

Problem with all the varying temps is the ecu has to constantly adjust for that. Are you getting the most efficient/best power return when the fueling is constantly changing?

If you are looking for power, you probably want the cooler running engine.

I agree the more stable the engine temp the better. In reality these liquid cooled engines are FAR more thermally stable than air cooled engines.

It's a trade off on when the fan comes on. If you bring it on sooner then the fan ends up running a great deal of the time, not necessarily ideal. In the ECU programming for my Triumph Speed Triple I can adjust what temperature the fan kicks in, nice. But with these bikes you either find a different temp switch or somehow bias the signal to get it to come on earlier. In practice I think the stock setup is not that far off from a practical overall solution.

As I mentioned, with the changes I've made I don't encounter the higher temps that often and when I'm sitting at a stop light I'm not so worried about max power. With my dual fan setup it brings the temp back down quite rapidly. When I was calibrating the temps they would start to fall very quickly after the fans kicked on and fell about 1 degree every minute or so but that's the fans only, the bike was not moving. If you start to move, say pulling away from that stop light, it cools much faster with the additional air flow.

One of the mods I felt really helped was the holes in the back of the fender. I saw the temps become much more stable at low speeds with this change as more air flowed through the radiator.

When I'm moving most of the time it sits right on the thermostat temp, which I'd estimate around 200 degrees.

Oregoner

Husqvarna

AA Class

The delete doesn't effect that, but the waterless coolant will. Water stores energy, but it takes longer to absorb and release it. Waterless coolant on the other hand, absorbs and releases energy quickly. Waterless coolant comes up to operating temperature much faster than with water.

I'm wondering if there's some confusion or misunderstanding here. Hey, it could be me. BUT a fluid that reacts FASTER to heat by way of temperature increase has a REDUCED cooling capacity.

It takes 1 BTU to raise 1 lb of water 1F. A lot of other fluids will only absorb a fraction of that heat before they have the same rise in temperature. So they APPEAR to react faster but in fact have LESS cooling capacity by weight.

Does that make sense?