-

Hi everyone,

As you all know, Coffee (Dean) passed away a couple of years ago. I am Dean's ex-wife's husband and happen to have spent my career in tech. Over the years, I occasionally helped Dean with various tech issues.

When he passed, I worked with his kids to gather the necessary credentials to keep this site running. Since then (and for however long they worked with Coffee), Woodschick and Dirtdame have been maintaining the site and covering the costs. Without their hard work and financial support, CafeHusky would have been lost.

Over the past couple of weeks, I’ve been working to migrate the site to a free cloud compute instance so that Woodschick and Dirtdame no longer have to fund it. At the same time, I’ve updated the site to a current version of XenForo (the discussion software it runs on). The previous version was outdated and no longer supported.

Unfortunately, the new software version doesn’t support importing the old site’s styles, so for now, you’ll see the XenForo default style. This may change over time.

Coffee didn’t document the work he did on the site, so I’ve been digging through the old setup to understand how everything was running. There may still be things I’ve missed. One known issue is that email functionality is not yet working on the new site, but I hope to resolve this over time.

Thanks for your patience and support!

You should upgrade or use an alternative browser.

Highway Dirtbike Handguards for TE 310

- Thread starter 2wheeler

- Start date

reveille

Husqvarna

Pro Class

For the TE's the bolt pattern is 93x50mm, but I don't support the 50mm top clamps anymore because they're asymmetrical, what I'm making is 93x38/40mm and then the lowers I make for everything else matches those. So when you order you need to order lowers too. That's the only special consideration you'll need, the through bolts are 10mm.

reveille

Husqvarna

Pro Class

2wheeler

Husqvarna

AA Class

reveille

Husqvarna

Pro Class

Mike-AK

Husqvarna

Pro Class

You will need to tap your bar ends. Make sure you are fresh when you attempt it. Don't try doing it after work because you will end up running out of cuss words. AMHIK Much better to tackle it early in your day IMO. I replaced my bars with Protaper EVO's, my current favorite bars and the flex helps with vibes too. If your not gluing the grips then safety wire them.

If I had to do it over I would make a tap guide out of PVC or something to keep the tap straight when starting. If it gets crooked in the hole, chances are the guards will still bolt up, but it will be a big PITA getting enough thread depth while the tap tries to chew its way through the bar. Ask me how I know...

reveille

Husqvarna

Pro Class

2wheeler

Husqvarna

AA Class

Mike-AK

Husqvarna

Pro Class

Thanks reveille. Paul's explanation alleviates my confusion lol.

Picked up some pillow top grips. Going to try not gluing them. Maybe they will help a little with vibration.

I recommend gluing them. I painted the bars with Goop and let it dry, then I brushed on some mineral spirits and also sloshed mineral spirits around inside the grips and twisted them on. It took a little effort, but they are on there rock solid now. If you don't have one, now would be a good time to by a grip punch cutter to cut out the ends of the grips.

Mike-AK

Husqvarna

Pro Class

We will go with the gluing. Mike by Goop you refer to the glue right? Why the mineral spirits?

GOOP is a brand of rubber cement. I imagine any would work. It sets after you paint it on the bars. The mineral spirits dissolve it again just enough that you can slide the grips on.

Mike-AK

Husqvarna

Pro Class

You can probably get the old grips off intact if you are careful. Compressed air can help. If not, you will need new ones. Either way you will need to cut holes in the end of them since the bar ends need to be uncovered to attach the HDB handguards. A grip punch cutter is the neatest way to do that. This would also be a good time to install a Throttle Tamer if you are so inclined.

kensea

Husqvarna

A Class

FNG to the world of off-road and all the inherent mysteries. A "tap guide" made out of PVC or a 2x4; how do you make it and then use it ? Sorry, but I have not run across the need for one in my casual wrenching, so any and all information would be appreciated. Thanks, Ken.

reveille

Husqvarna

Pro Class

2wheeler

Husqvarna

AA Class

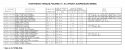

Am I interpreting the correct torque figures for the risers, and the top clamp?

Risers to Triple Clamp 28 Nm

HDB Top Clamp to Risers 21 Nm

The bolts holding the risers to the triple clamp don't seem to be long enough for the provided flat washer. I should be OK with the factory triple clamp grommet/washers combo right?

Now for the Up Tite Skidplate shipped email

Now for the Up Tite Skidplate shipped email