bobnoxious67

Husqvarna

AA Class

Hey guys...hope this is the right spot to put this.

I'm changing out the fork seals (AGAIN) on my '09 TE450, and while I'm in there I would like to soften the compression valve shim stack a touch...like nearly everybody else on the planet I feel they are too harsh on the sharp hits like rocks and roots, deflecting the front end all over the place, especially when going up gnarly uphills. It's good in faster/hard hitting whoops and such.

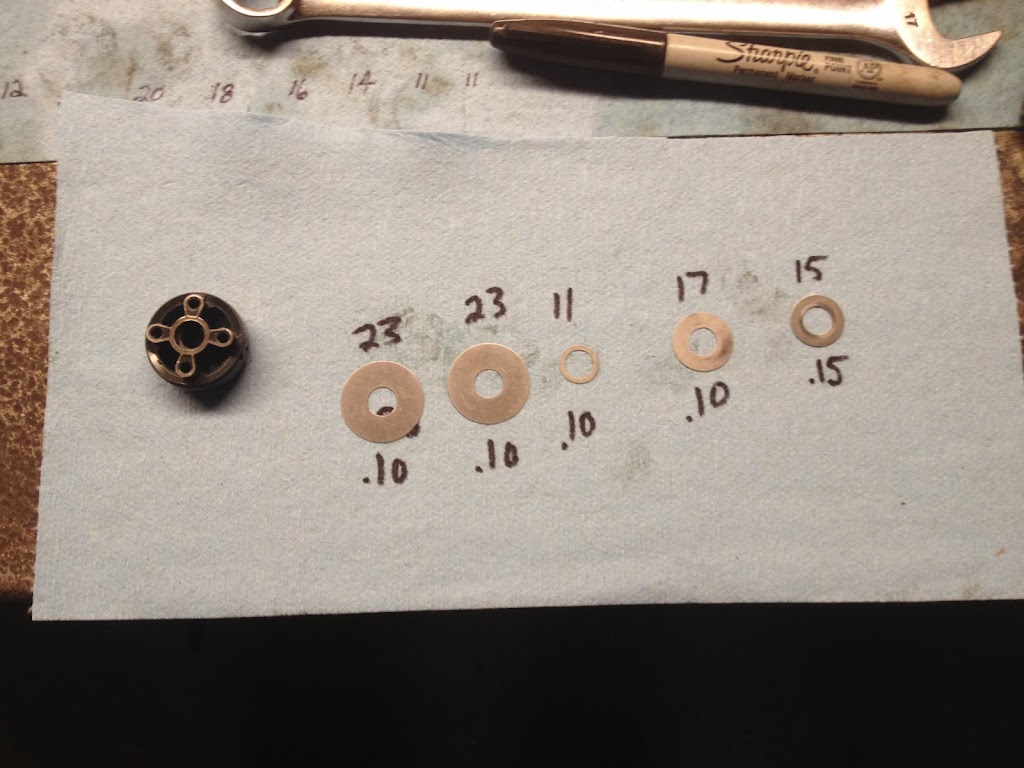

Here is my stack. If you were going to remove a shim(s) and/or move some around, which ones? Is the one with the arrow called a "bleed shim"? Rumor that the harshness actually comes from not enough damping, and that removing this one helps...? I run my compression clickers all the way out, it's the only thing that makes them bearable.

I'm changing out the fork seals (AGAIN) on my '09 TE450, and while I'm in there I would like to soften the compression valve shim stack a touch...like nearly everybody else on the planet I feel they are too harsh on the sharp hits like rocks and roots, deflecting the front end all over the place, especially when going up gnarly uphills. It's good in faster/hard hitting whoops and such.

Here is my stack. If you were going to remove a shim(s) and/or move some around, which ones? Is the one with the arrow called a "bleed shim"? Rumor that the harshness actually comes from not enough damping, and that removing this one helps...? I run my compression clickers all the way out, it's the only thing that makes them bearable.

ive been looking for a penny washer just like that to clamp my exhaust up! loads in my suspension i see.

ive been looking for a penny washer just like that to clamp my exhaust up! loads in my suspension i see.

The rebound stack on my TE is just 6X 23.1, and it works fine but is on the lighter side. Yours is quite a bit lighter...

The rebound stack on my TE is just 6X 23.1, and it works fine but is on the lighter side. Yours is quite a bit lighter...