9880sts

Husqvarna

AA Class

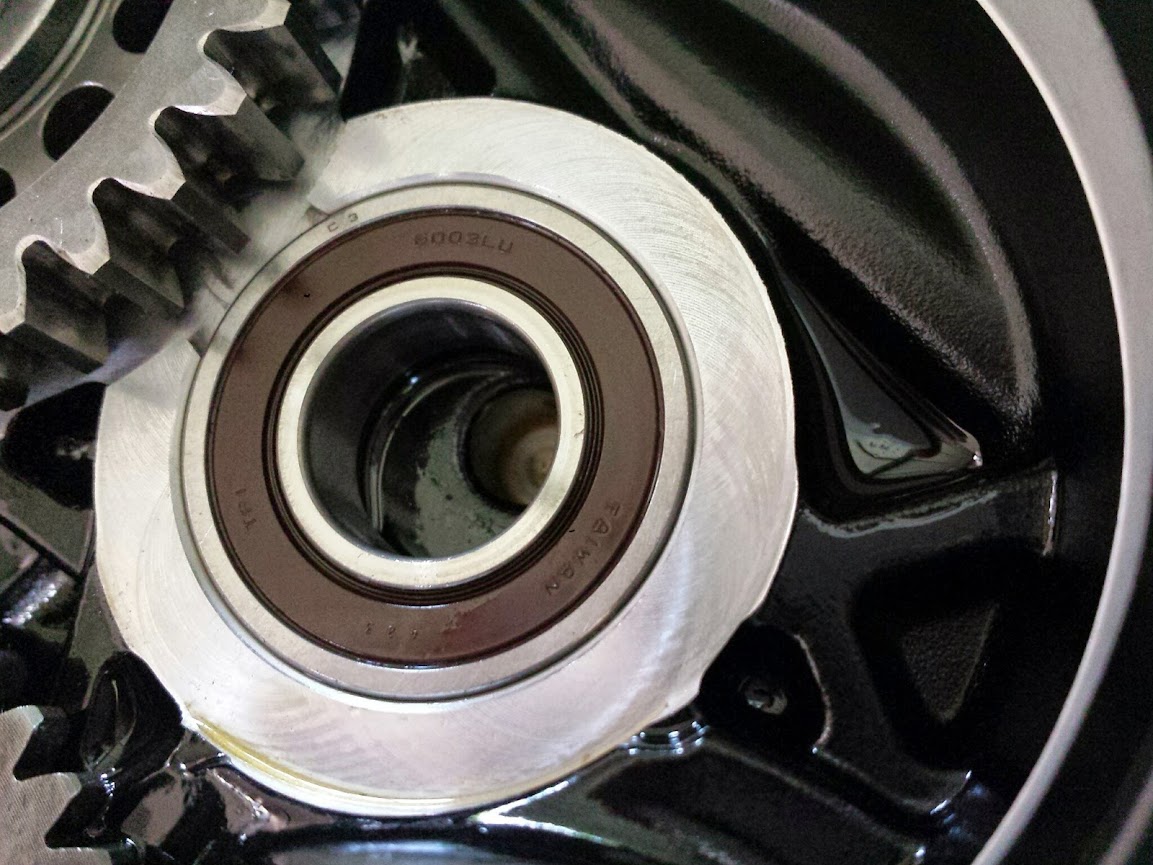

Just did my TL replacement on the TE511 2013 model.

Now i did have a chat with my Dealer , and this also possible on the 2011 model. I went there and checked the frame and bolts... it is the same as on the 2013. Some mechanics dont even remove engine mounts at all. Just loosen the bolts and leave em in the Cover while you slide it out and back in.

Not as bad as it looks... DIY possible.

Now i did have a chat with my Dealer , and this also possible on the 2011 model. I went there and checked the frame and bolts... it is the same as on the 2013. Some mechanics dont even remove engine mounts at all. Just loosen the bolts and leave em in the Cover while you slide it out and back in.

Not as bad as it looks... DIY possible.

umm... digging through pictures now

umm... digging through pictures now

it made it to production.....

it made it to production.....