COFFEE EDIT, link to discussion thread LINK

I looked around a lot and could not find much information related to stripping and re applying Hardcoat Type III Anodize to the inside and outside of my fork tubes on my 2005 TC450

Had several conversations

with Les @ LTR , Race-Tech, Clay @ 7602, and Coastline Metal Finishing in the OC!

with Les @ LTR , Race-Tech, Clay @ 7602, and Coastline Metal Finishing in the OC!

Had to do this because of a blown fork spring while riding at Pala MX a few weeks back:

Starting point is to remove the forks from the bike and then take the tubes apart. Loosen or remove the fork caps while still in the triples. Drain all oil. Hit the bottom nut on the very bottom of the fork with an air impact. This will let the damping rod release from the lower.

Pop/pry the dust seal out from the end of each tube. Use a small flat screw driver and a small piece of wood underneath it so that the screwdriver doesn't mark up the end of the upper fork tube.

Remove the spring retainer snap ring. Pull the shaft out of the tube. May take three or four good slide pull actions to let it pop out. Uppers are now off:

Clean Fork tube and ensure that there are no wear spots on the inside of the tube where the triple clamp pinch bolts tighten. Look for wear on the inside. Hold a clean tube up to a light or the sky and look through it while rotating 360 degrees

Note: the inside and the outside have been Hard Anodized type III from the factory. If you see wear spots on the inside, you must completely strip the anodize off of theinside and outside of the fork tube.

Some people say that you can re-hardcoat over the existing Hardcoat anodize. While possible, this is not a good option as the Sulphuric Bath that is used in reapplying a new coat of hardcoat is used, it will soften the original layer of hardcoat and them will remain soft as an underlayer when the new layer is applied. It will wear very qucily as it is not as hard as a solid uniform coat.

The inside of the tubes needs to be very clean and smooth after stripping.

Once tube has been stripped, re-apply Hardcoat Type III anodize in the color of your choice ( I wanted Black) . It should be reapplied in a thickness range of approximately.0010" to .0015" per side. This gives you a total buildup on the ID diameter of approx .002 to .003"

As advised by Race-Tech this is a good wear layer thickness.

Inspect I.D. of tube for clean smooth finish. If necessary the ID can be lightly buffed or honed . ( mine came out very clean and smooth - no need to hone) ( as a side note, I called Race Tech

and they will hone for approximately $30)

and they will hone for approximately $30)

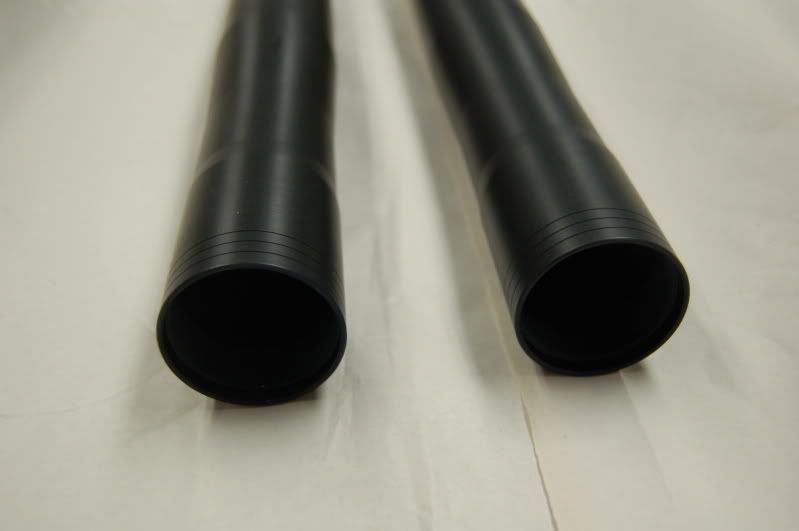

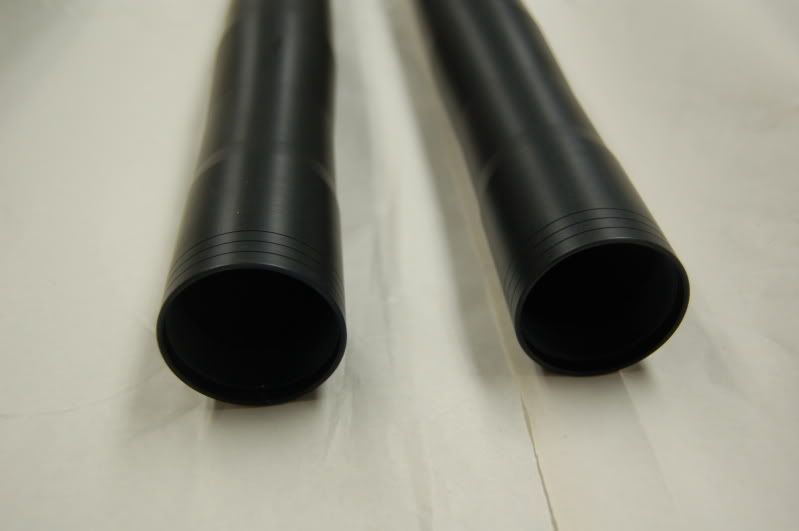

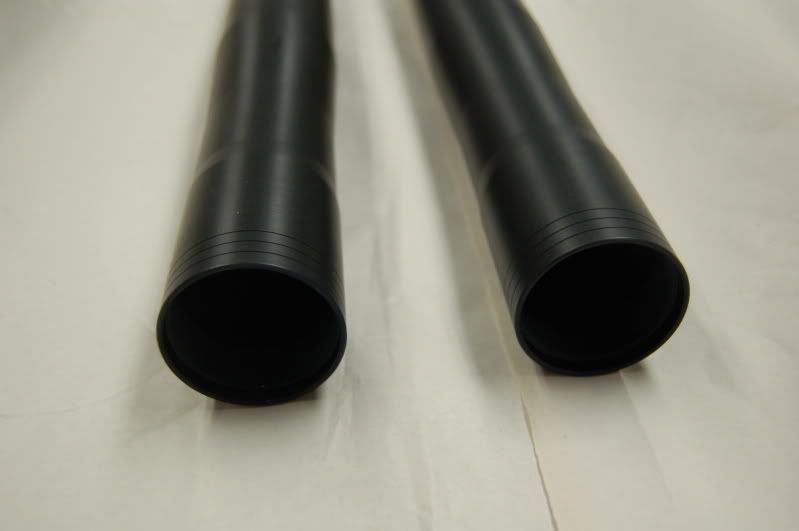

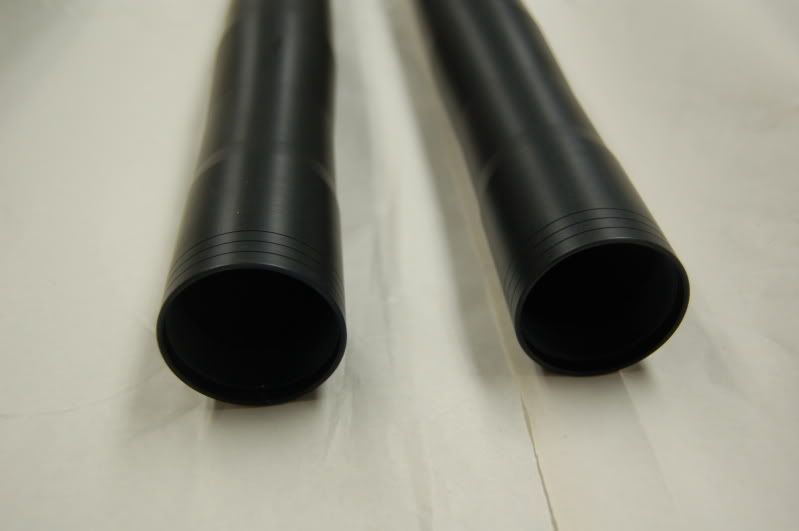

Here are my freshly Hard Anodized Upper Fork tubes ( ready to go to Les @ LTR

for a full service rebuild:

for a full service rebuild:

Hope this helps out anyone thinking about re-hardcoating or changing the anodized colors of their fork tubes!

T

I looked around a lot and could not find much information related to stripping and re applying Hardcoat Type III Anodize to the inside and outside of my fork tubes on my 2005 TC450

Had several conversations

with Les @ LTR , Race-Tech, Clay @ 7602, and Coastline Metal Finishing in the OC!

with Les @ LTR , Race-Tech, Clay @ 7602, and Coastline Metal Finishing in the OC!Had to do this because of a blown fork spring while riding at Pala MX a few weeks back:

Starting point is to remove the forks from the bike and then take the tubes apart. Loosen or remove the fork caps while still in the triples. Drain all oil. Hit the bottom nut on the very bottom of the fork with an air impact. This will let the damping rod release from the lower.

Pop/pry the dust seal out from the end of each tube. Use a small flat screw driver and a small piece of wood underneath it so that the screwdriver doesn't mark up the end of the upper fork tube.

Remove the spring retainer snap ring. Pull the shaft out of the tube. May take three or four good slide pull actions to let it pop out. Uppers are now off:

Clean Fork tube and ensure that there are no wear spots on the inside of the tube where the triple clamp pinch bolts tighten. Look for wear on the inside. Hold a clean tube up to a light or the sky and look through it while rotating 360 degrees

Note: the inside and the outside have been Hard Anodized type III from the factory. If you see wear spots on the inside, you must completely strip the anodize off of theinside and outside of the fork tube.

Some people say that you can re-hardcoat over the existing Hardcoat anodize. While possible, this is not a good option as the Sulphuric Bath that is used in reapplying a new coat of hardcoat is used, it will soften the original layer of hardcoat and them will remain soft as an underlayer when the new layer is applied. It will wear very qucily as it is not as hard as a solid uniform coat.

The inside of the tubes needs to be very clean and smooth after stripping.

Once tube has been stripped, re-apply Hardcoat Type III anodize in the color of your choice ( I wanted Black) . It should be reapplied in a thickness range of approximately.0010" to .0015" per side. This gives you a total buildup on the ID diameter of approx .002 to .003"

As advised by Race-Tech this is a good wear layer thickness.

Inspect I.D. of tube for clean smooth finish. If necessary the ID can be lightly buffed or honed . ( mine came out very clean and smooth - no need to hone) ( as a side note, I called Race Tech

and they will hone for approximately $30)

and they will hone for approximately $30)Here are my freshly Hard Anodized Upper Fork tubes ( ready to go to Les @ LTR

for a full service rebuild:

for a full service rebuild:

Hope this helps out anyone thinking about re-hardcoating or changing the anodized colors of their fork tubes!

T

dialed in my forks once again....

dialed in my forks once again....