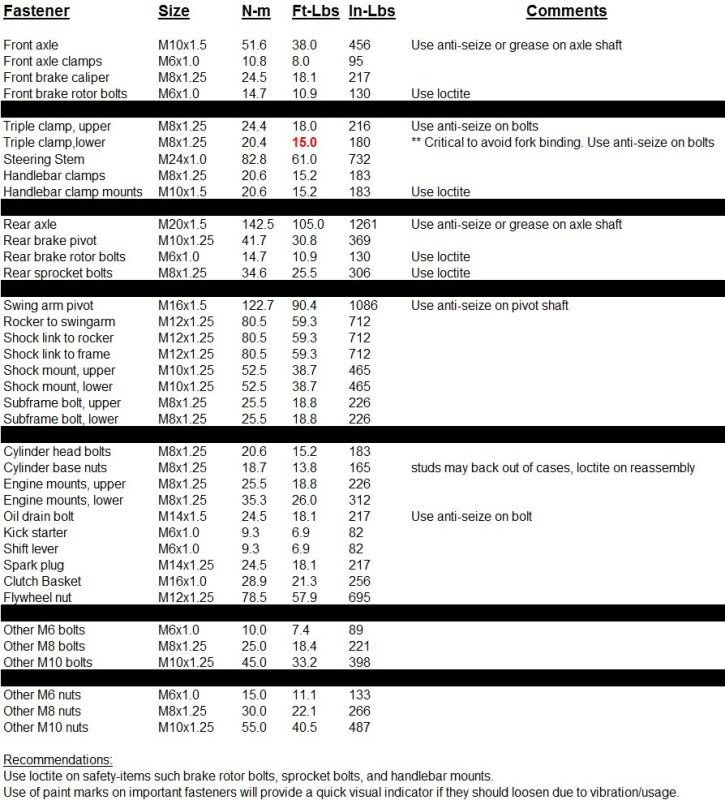

Fastener Torque Table

Here is a reference table that I created for my 2008 CR125. It may be applicable to other year CR,WR 125/150 bikes. The WR250/300 bikes may be different.

Note: As indicated in (red), I use a slightly lower torque value for the Triple Clamp Lower Bolts. This is done to avoid fork binding.

DISCLAIMER: This table does not replace your owner's manual.

It is for quick reference after you have verified that these torque values are suitable to your bike.

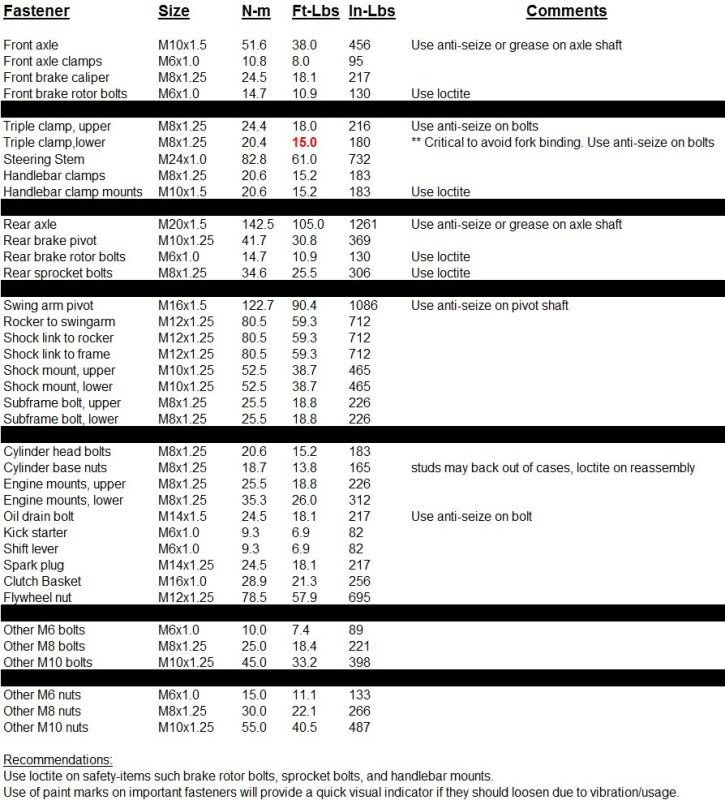

Here is a reference table that I created for my 2008 CR125. It may be applicable to other year CR,WR 125/150 bikes. The WR250/300 bikes may be different.

Note: As indicated in (red), I use a slightly lower torque value for the Triple Clamp Lower Bolts. This is done to avoid fork binding.

DISCLAIMER: This table does not replace your owner's manual.

It is for quick reference after you have verified that these torque values are suitable to your bike.

I was looking for this for my next bike (2012 cr125) thanks!

I was looking for this for my next bike (2012 cr125) thanks!