DYNOBOB

Husqvarna

Pro Class

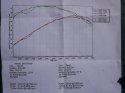

With 500+ miles and an oil change on the new bike I decided to put it on the dyno for some testing. It was eye opening and a little disappointing...

Some thoughts in no particular order.

Part of me cannot understand why you would take a new vehicle with a modern closed loop fuel injection system and turn it into a open loop "blind" system by removing the O2 sensor and plugging in a resistor. No one would buy a new car and do this. The point of a closed loop system is to monitor the AFR real time and adjust the mixture to an optimum setting, not too rich and not too lean. I realize that when you modify the exhaust/intake systems that you may need a mechanism (ie. power commander/JD tuner) to adjust the fuel delivery and compensate. However, in stock condition I have an expectation that my new vehicle is running efficiently and has good driveability. Based on what I've found I'm a little disappointed in the product Husky sent me out the door with.

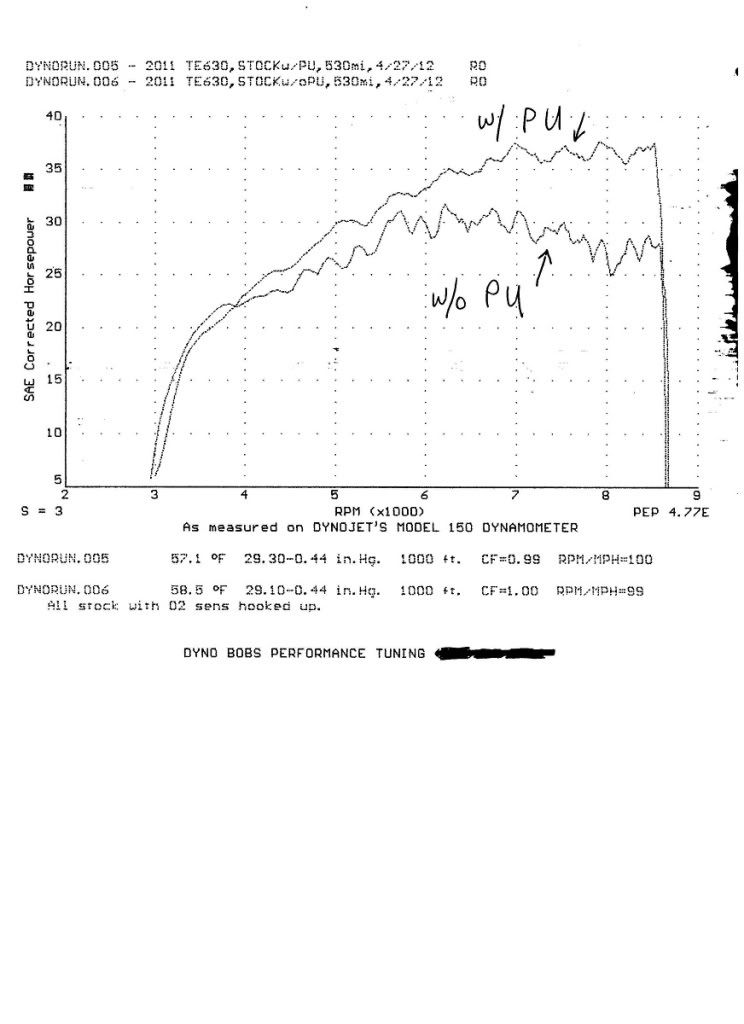

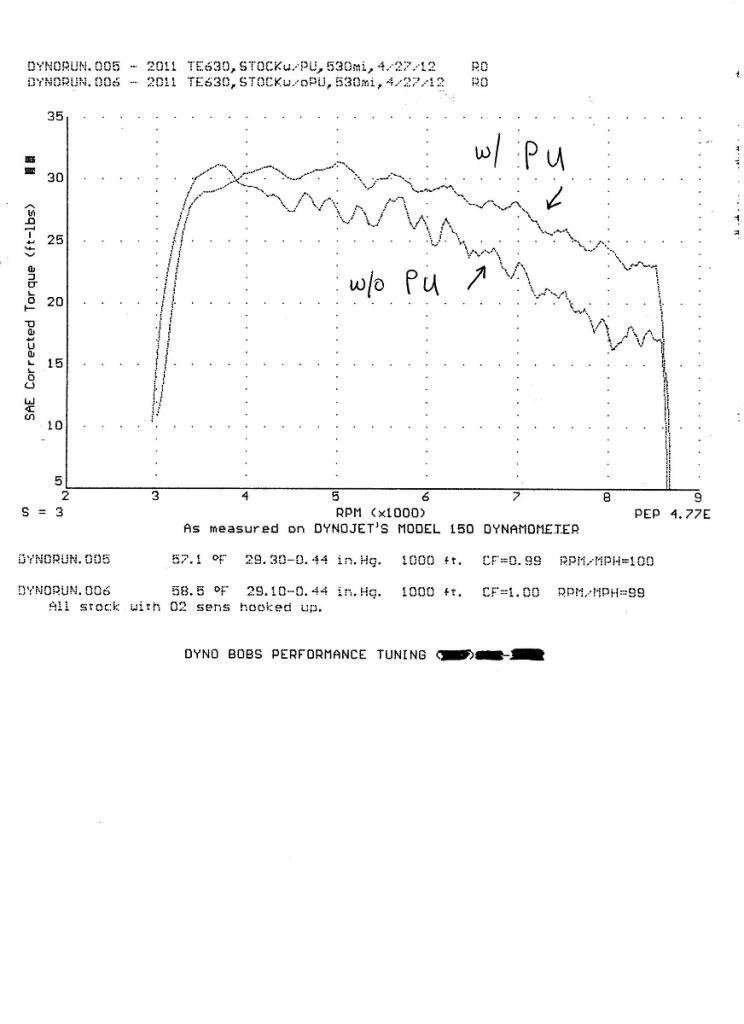

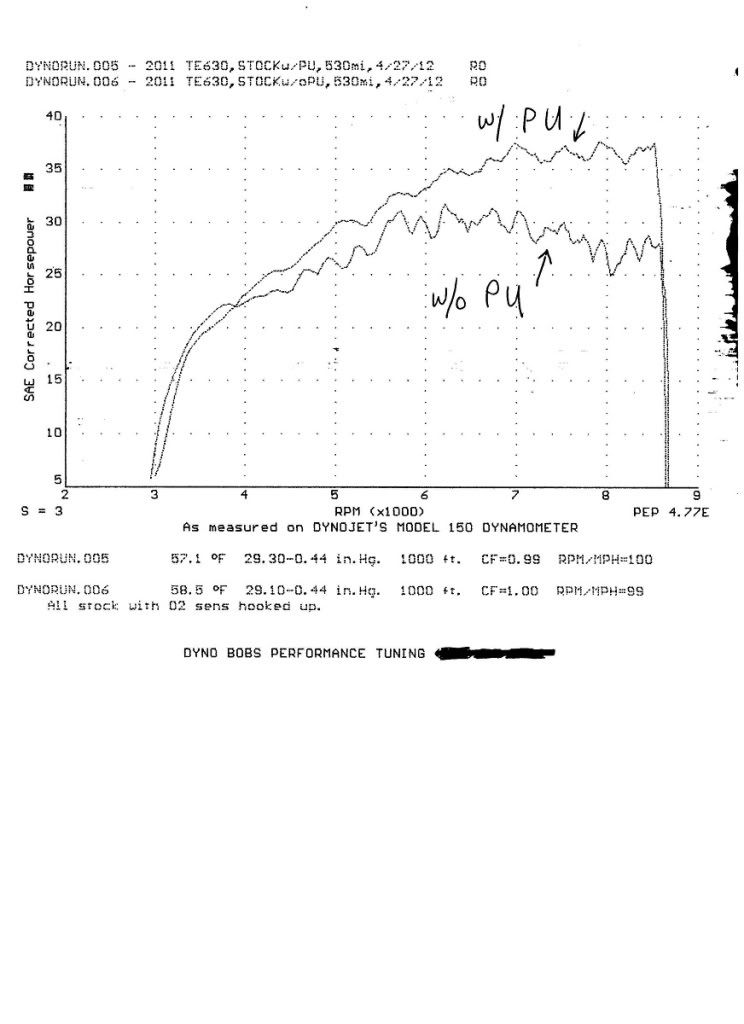

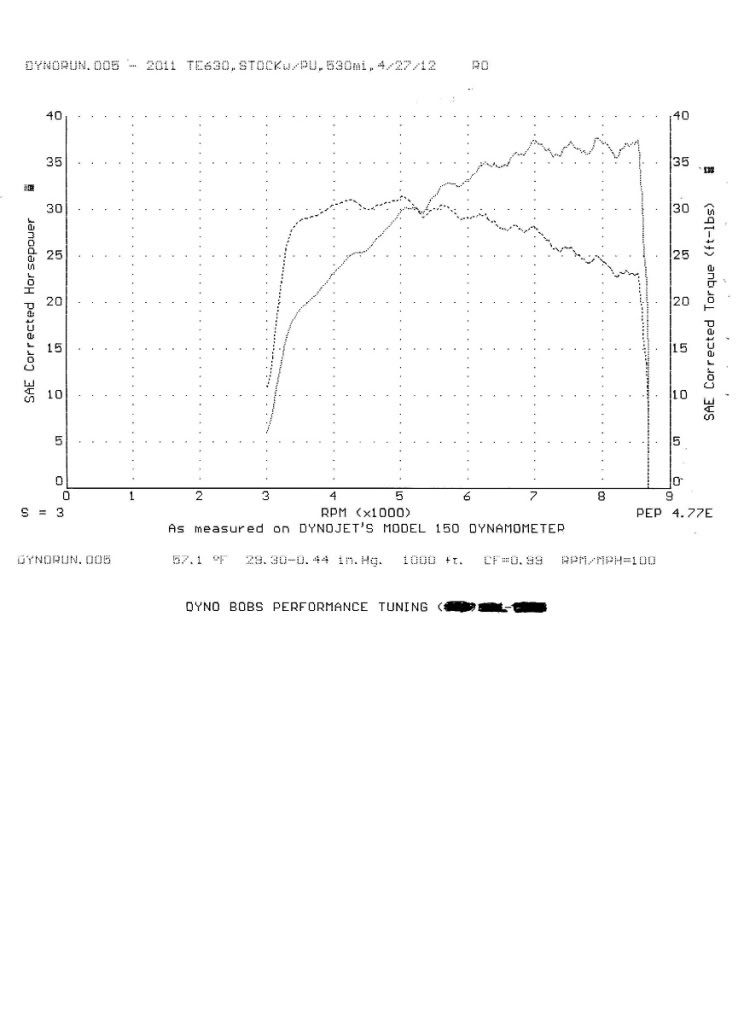

Since my TE630 had the PU kit installed when I bought it new I dyno'd it in that condition first. It made ~35hp and the roughness of the graph curve made me guess it was lean. I pulled the plug out of the O2 sensor port and screwed in the O2 sensor to my Innovate LM-1 AFR meter and did some pulls watching the A/F ratio. At idle the bike was running ~14.2 afr (not horrible) and under full throttle it went to 15s and 16s (rather lean). That would explain the jagged power graph.

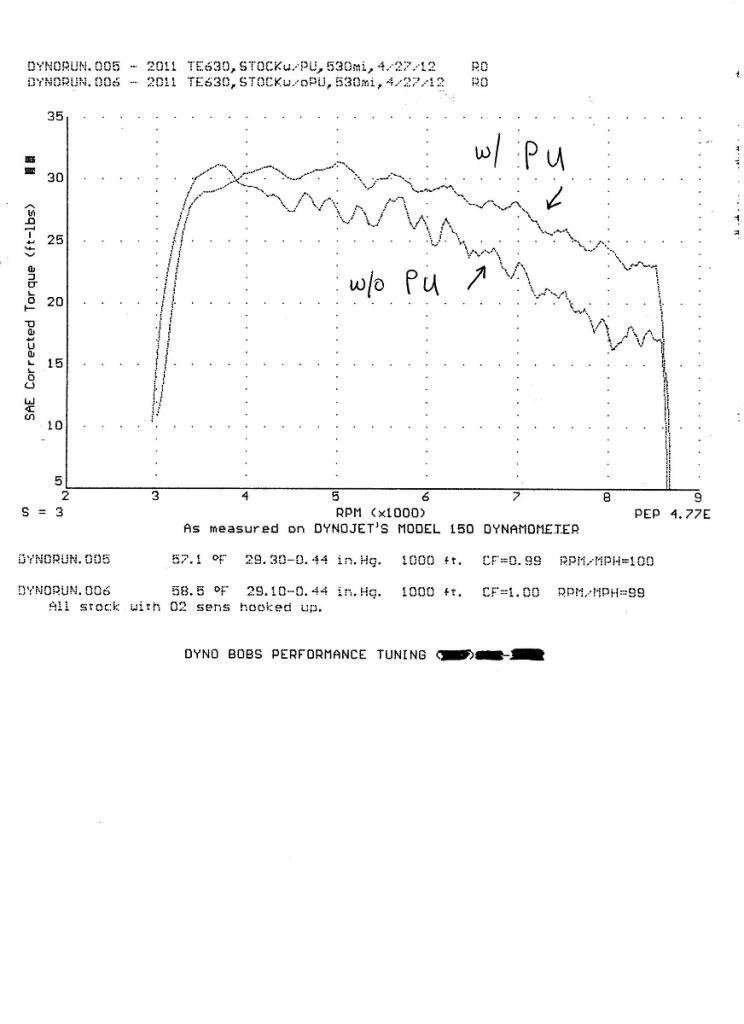

I had intentions all along of removing the PU kit and checking the bike with the O2 sensor back in (restoring the closed loop FI system). Note: putting the stock O2 back in meant I could no longer use the Innovate to watch A/F ratio, the exhaust pipe probe with the Innovate will not fit in the Husky exhaust. Well, it's not news that these bikes run like crap w/o the PU kit and this was evident on the dyno. Power output fell to ~30hp and the graph looks terrible. I think it's safe to say that the bike was now ungodly lean. So lean, that I think operating the bike under a hard load in higher gears for long periods of time could hurt the bike.

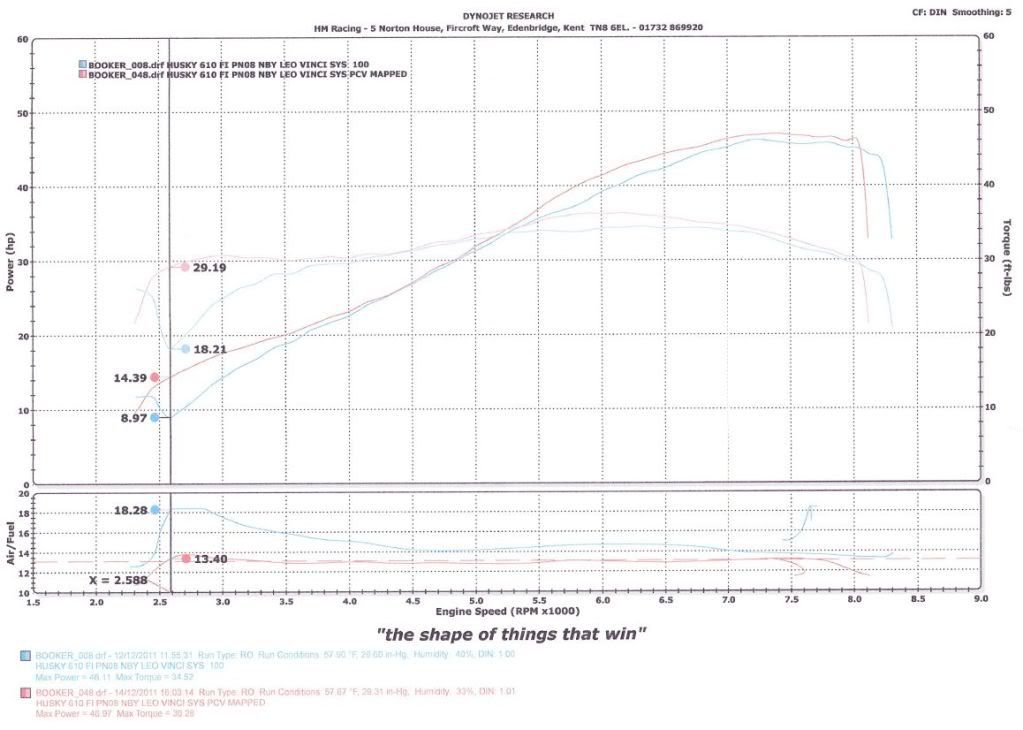

Reality is reality though so I'll be purchasing a PC-V or JD tuner to hopefully get this thing in the low-mid 40hp range. I'm leaning toward the JD (wish someone close by had one I could try or dyno their bike...). It burns my butt a little that I have to buy a $300 part to make my new bike run decent...I would not have to do this if I bought a F800GS or Tiger 800XC.

Here's an interesting tidbit. I did a free-air calibration of the Innovate before installing the sensor. I installed it and warmed up the bike while watching the AFR. After a few minutes I turned on the cooling fan that blows on the front of the bike and when I did the AFR went goofy (40-50). I'm guessing there is a exhaust leak somewhere so I tightened everything and found the bolts a little loose at the head. The other possibility is the AFR was affected by the cold air blowing on the header pipes (however this is a condition you'd encounter just riding the bike). Anyway, pulled the sensor and re-calibrated and it then acted better. The reason I mention this is it makes the argument for switching to a open loop system (the PU kit and JD tuner) and putting the settings where the bike runs best/makes the best hp...you'd have no exposure to the O2 sens making a faulty reading.

Anyway, there's more than you wanted to know about what I did today. Don't get me wrong, I love my TE. It checked off more boxes for me than any other on/off road bike out there and this little wrinkle can be corrected. I'll report the dyno results once the tuner is added.

A few pics of my setup.

HP

Torque

Tach signal wire is white/red stripe at ecu.

Some thoughts in no particular order.

Part of me cannot understand why you would take a new vehicle with a modern closed loop fuel injection system and turn it into a open loop "blind" system by removing the O2 sensor and plugging in a resistor. No one would buy a new car and do this. The point of a closed loop system is to monitor the AFR real time and adjust the mixture to an optimum setting, not too rich and not too lean. I realize that when you modify the exhaust/intake systems that you may need a mechanism (ie. power commander/JD tuner) to adjust the fuel delivery and compensate. However, in stock condition I have an expectation that my new vehicle is running efficiently and has good driveability. Based on what I've found I'm a little disappointed in the product Husky sent me out the door with.

Since my TE630 had the PU kit installed when I bought it new I dyno'd it in that condition first. It made ~35hp and the roughness of the graph curve made me guess it was lean. I pulled the plug out of the O2 sensor port and screwed in the O2 sensor to my Innovate LM-1 AFR meter and did some pulls watching the A/F ratio. At idle the bike was running ~14.2 afr (not horrible) and under full throttle it went to 15s and 16s (rather lean). That would explain the jagged power graph.

I had intentions all along of removing the PU kit and checking the bike with the O2 sensor back in (restoring the closed loop FI system). Note: putting the stock O2 back in meant I could no longer use the Innovate to watch A/F ratio, the exhaust pipe probe with the Innovate will not fit in the Husky exhaust. Well, it's not news that these bikes run like crap w/o the PU kit and this was evident on the dyno. Power output fell to ~30hp and the graph looks terrible. I think it's safe to say that the bike was now ungodly lean. So lean, that I think operating the bike under a hard load in higher gears for long periods of time could hurt the bike.

Reality is reality though so I'll be purchasing a PC-V or JD tuner to hopefully get this thing in the low-mid 40hp range. I'm leaning toward the JD (wish someone close by had one I could try or dyno their bike...). It burns my butt a little that I have to buy a $300 part to make my new bike run decent...I would not have to do this if I bought a F800GS or Tiger 800XC.

Here's an interesting tidbit. I did a free-air calibration of the Innovate before installing the sensor. I installed it and warmed up the bike while watching the AFR. After a few minutes I turned on the cooling fan that blows on the front of the bike and when I did the AFR went goofy (40-50). I'm guessing there is a exhaust leak somewhere so I tightened everything and found the bolts a little loose at the head. The other possibility is the AFR was affected by the cold air blowing on the header pipes (however this is a condition you'd encounter just riding the bike). Anyway, pulled the sensor and re-calibrated and it then acted better. The reason I mention this is it makes the argument for switching to a open loop system (the PU kit and JD tuner) and putting the settings where the bike runs best/makes the best hp...you'd have no exposure to the O2 sens making a faulty reading.

Anyway, there's more than you wanted to know about what I did today. Don't get me wrong, I love my TE. It checked off more boxes for me than any other on/off road bike out there and this little wrinkle can be corrected. I'll report the dyno results once the tuner is added.

A few pics of my setup.

HP

Torque

Tach signal wire is white/red stripe at ecu.

once you get that leanness sorted i'm sure you will get more power but will need a JD or PC5 to do it.

once you get that leanness sorted i'm sure you will get more power but will need a JD or PC5 to do it.