AlwynMike

Husqvarna

A Class

So what do you do when you get a new bike?

You take it to pieces!

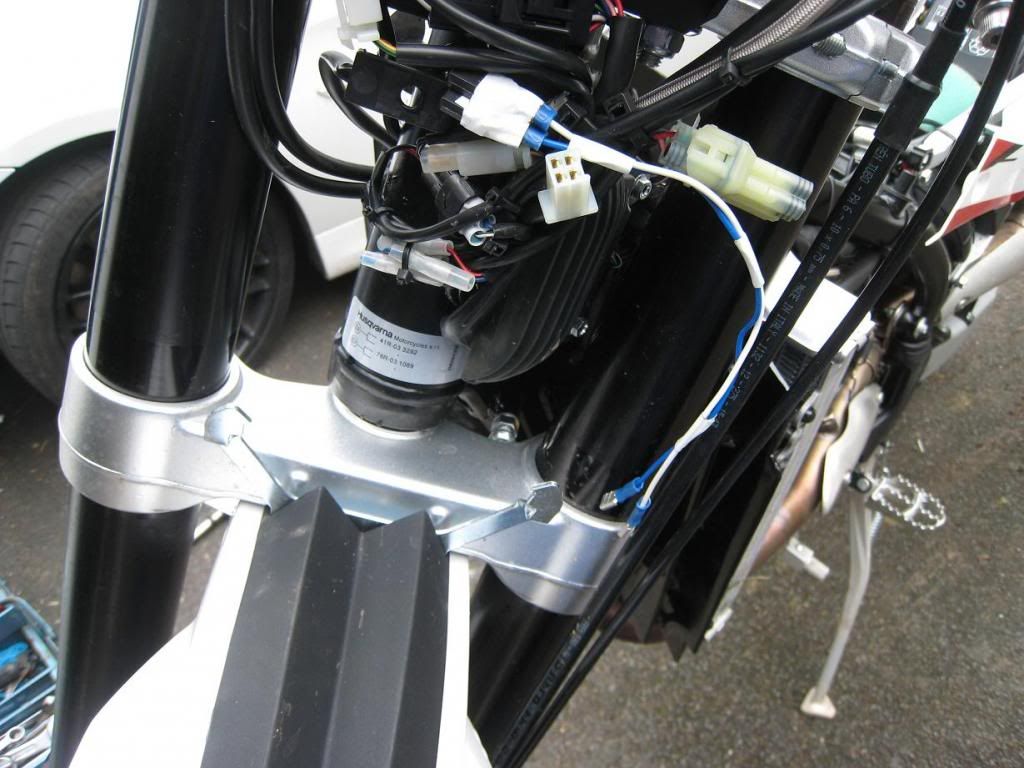

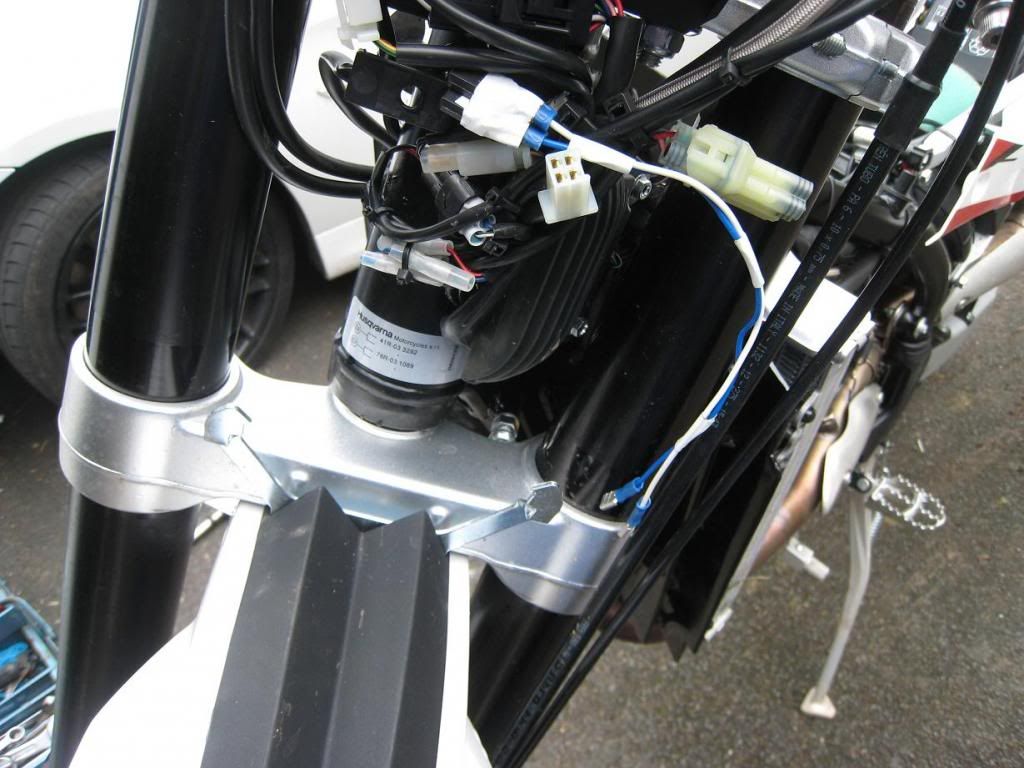

I didn't like the location of the horn in front of the radiator - it looked poor, so I decided to move it:

Off with the plastics and the tank. Horn and bendy bracket shown, with the wires disconnected.

Thread the wires past the headstock. Then extend them by a few inches. These are a bit long, but it makes it easier when I take the headlight unit off.

Out with the hacksaw to lose a few ounces of Italian tin. A random hole of a suitable size drilled ready.

A corresponding hole in the headlight unit steady, shown filled with a bolt from the workshop floor (its where you find the most useful stuff)

Horn securely mounted out of the way of mud and crud.

Connected up, ready to be fitted properly.

And now it's gone!!

You take it to pieces!

I didn't like the location of the horn in front of the radiator - it looked poor, so I decided to move it:

Off with the plastics and the tank. Horn and bendy bracket shown, with the wires disconnected.

Thread the wires past the headstock. Then extend them by a few inches. These are a bit long, but it makes it easier when I take the headlight unit off.

Out with the hacksaw to lose a few ounces of Italian tin. A random hole of a suitable size drilled ready.

A corresponding hole in the headlight unit steady, shown filled with a bolt from the workshop floor (its where you find the most useful stuff)

Horn securely mounted out of the way of mud and crud.

Connected up, ready to be fitted properly.

And now it's gone!!