So let me start by saying I am NOT a mechanic, I am finally got all the part to rebuild my 2010 TE310.

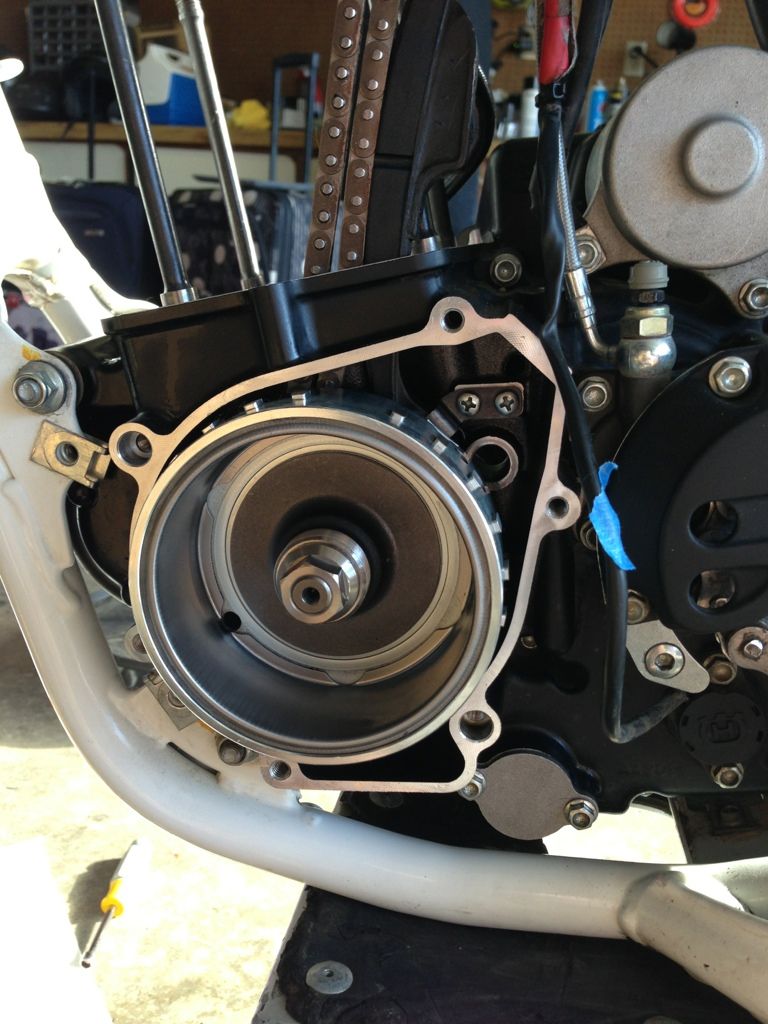

The flywheel was already off.

I put a new timing chain on and put the flywheel on and now I just need to tighten the nut per manual specs.

The manual says place aluminum shim in final gear...

I took the clutch cover off and tried to find someplace to wedge, with no luck.

what is the trick.

HELP!!! today is the day I have to do this

Thanks in advance

The flywheel was already off.

I put a new timing chain on and put the flywheel on and now I just need to tighten the nut per manual specs.

The manual says place aluminum shim in final gear...

I took the clutch cover off and tried to find someplace to wedge, with no luck.

what is the trick.

HELP!!! today is the day I have to do this

Thanks in advance