RuggedExposure

Now with more rugged!

I'm sure some of you are tired of seeing me derail threads with updates on my rear rack fabrication process. So I made a thread for those interested, and for the sanity of those who couldn't give a rat's ass.

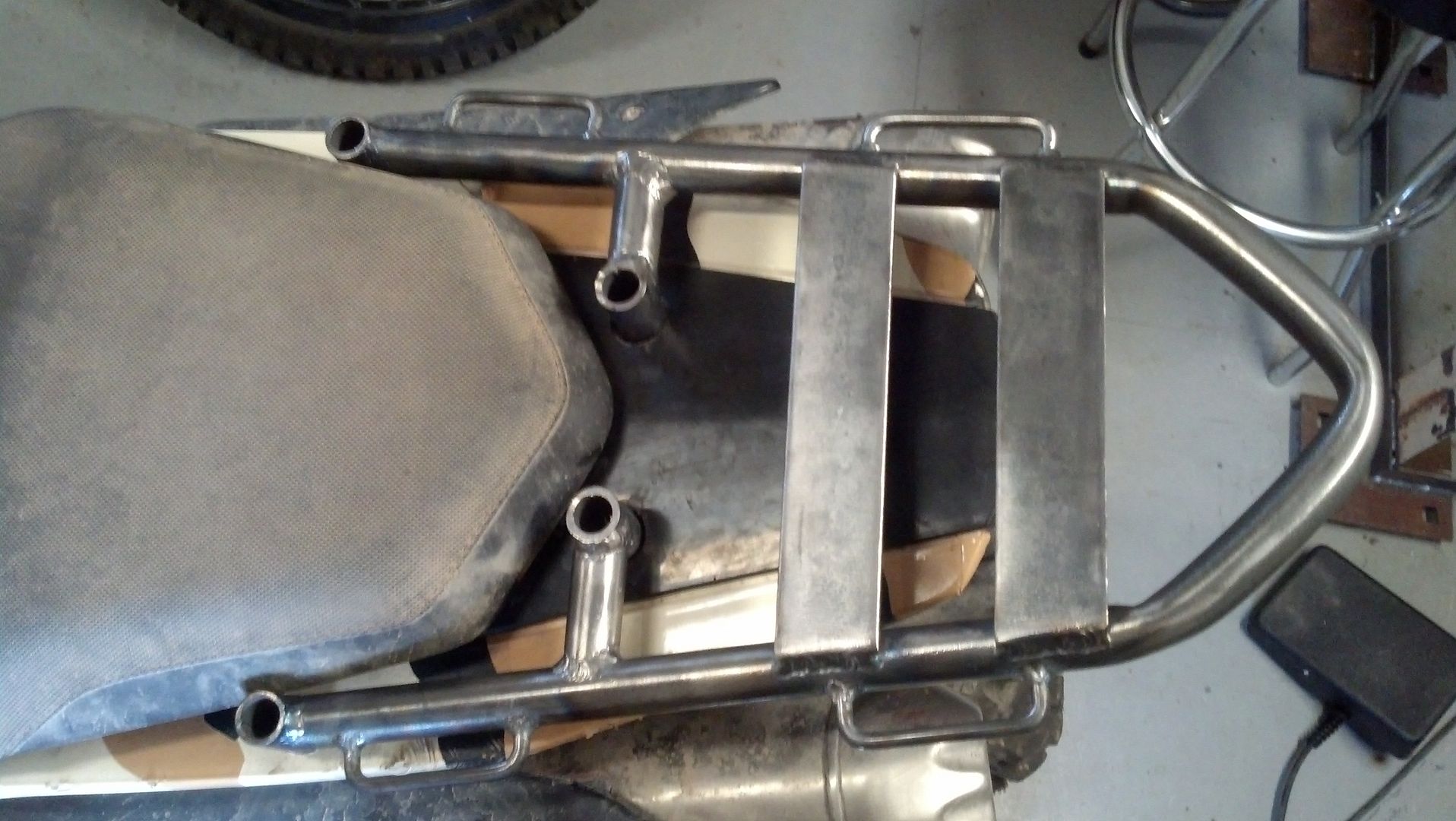

It all started with the craptastic factory rack snapping in half like it was from Kmart:

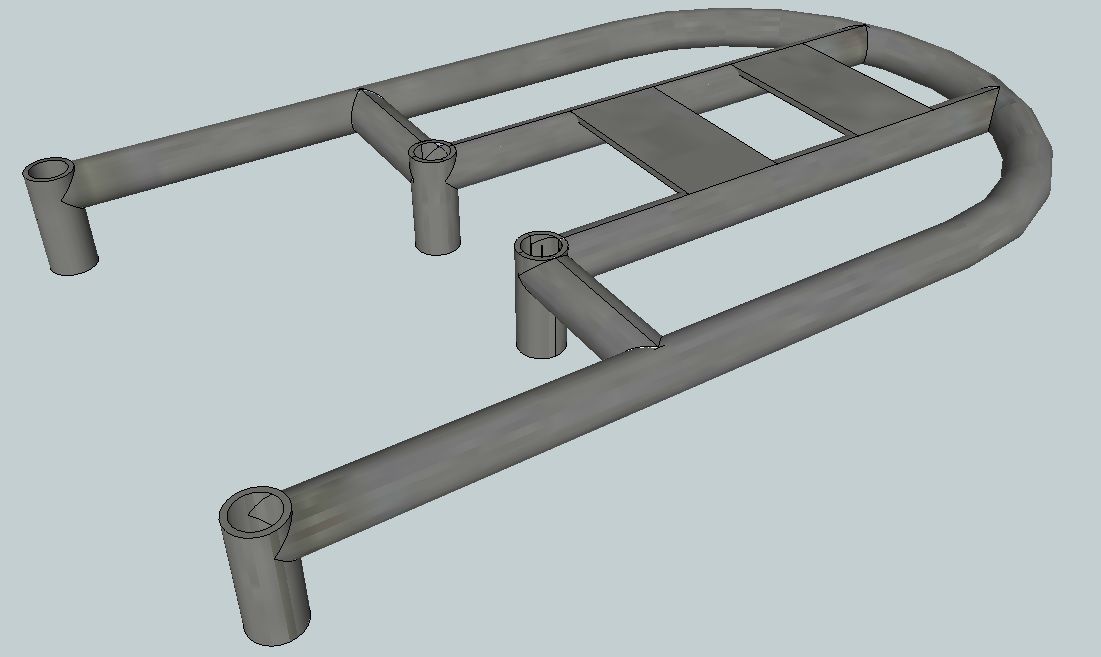

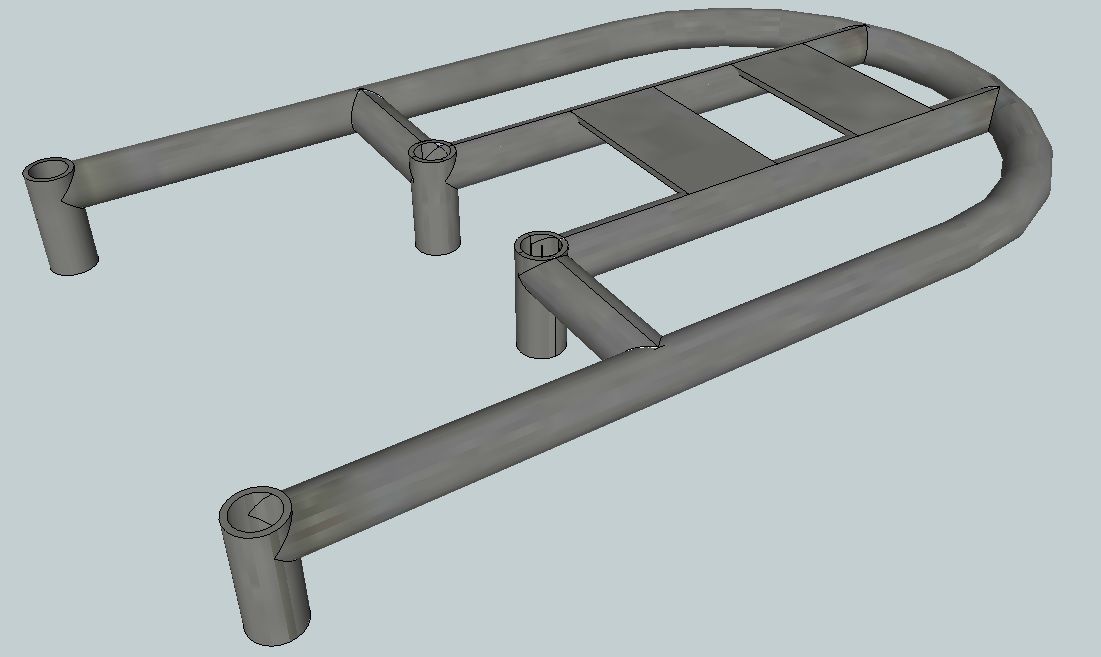

So I got down to working on a design for a heavy duty one in my free time:

I started with making the bend of the main hoop:

I fiddled around with the design and angles and ended up with this:

Turns out it was a bad idea having a stressed member be composed of 3 pieces when all I had to do was play around with the tubing bender and come up with something better. But I continued with this and made a template:

It all started with the craptastic factory rack snapping in half like it was from Kmart:

So I got down to working on a design for a heavy duty one in my free time:

I started with making the bend of the main hoop:

I fiddled around with the design and angles and ended up with this:

Turns out it was a bad idea having a stressed member be composed of 3 pieces when all I had to do was play around with the tubing bender and come up with something better. But I continued with this and made a template: